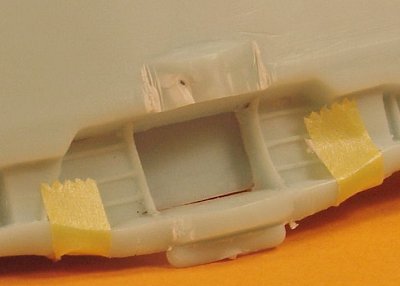

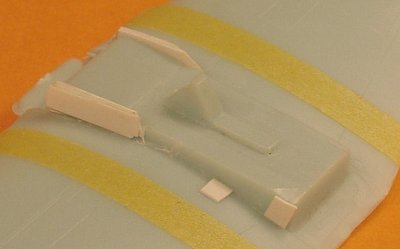

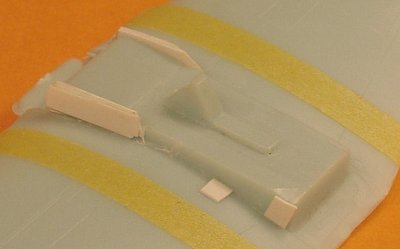

| The ordeal wasn't over yet. The fit of the fuselage halves around the wing was rather loose. It was quite possible to create zero dihedral on one wing, and way too much on the other. Also, it would be very easy to create unequal length wings by shifting the fuselage sideways! I decided to pack the cockpit floor to create a clearly defined fuselage position. I carefully put some pieces of tape on the wing to serve as reference lines. Because the fuselage halves appear to be of different thicknesses, I had to carve away some plastic at the right rear corner of the cockpit floor, add a thin spacer at the right front, a four times thicker one at the left front, and a thin one at the left rear. I also added a small spacer on the wing surface, because the left wing opening had become too large. The cockpit floor will need some cleaning up after this rough job, but that's for later.

|

|