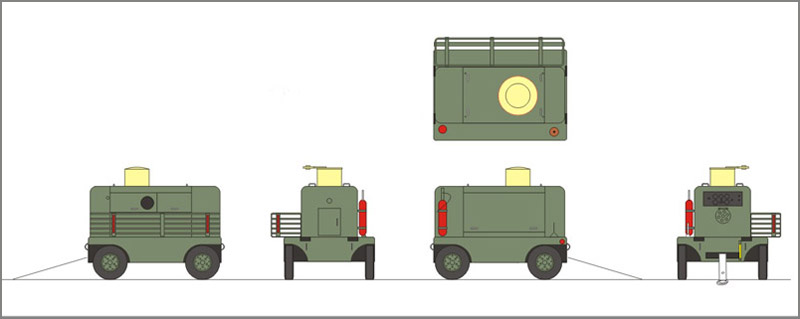

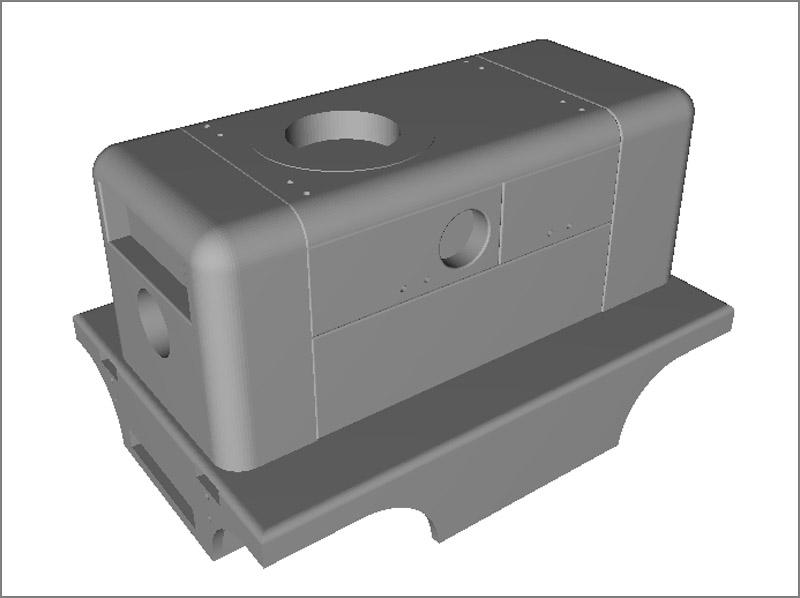

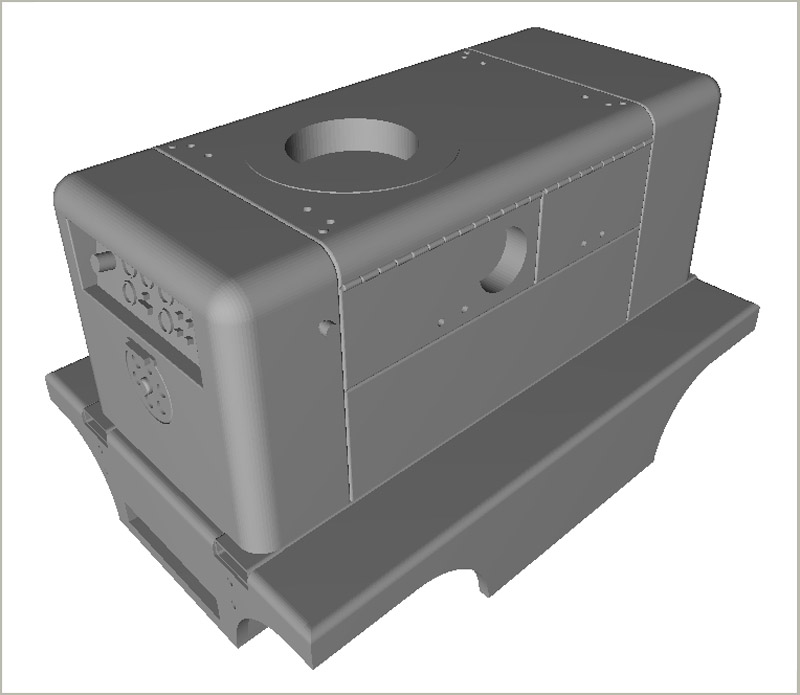

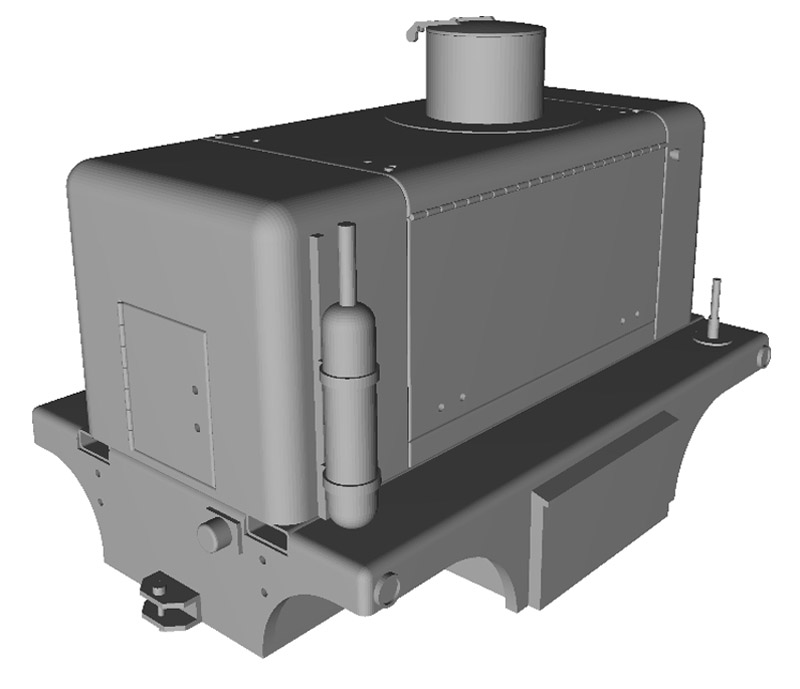

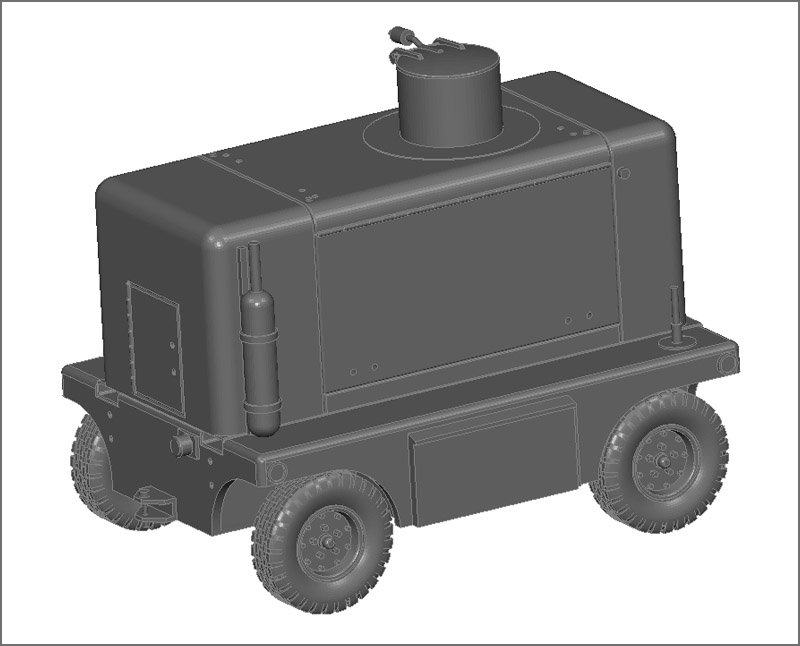

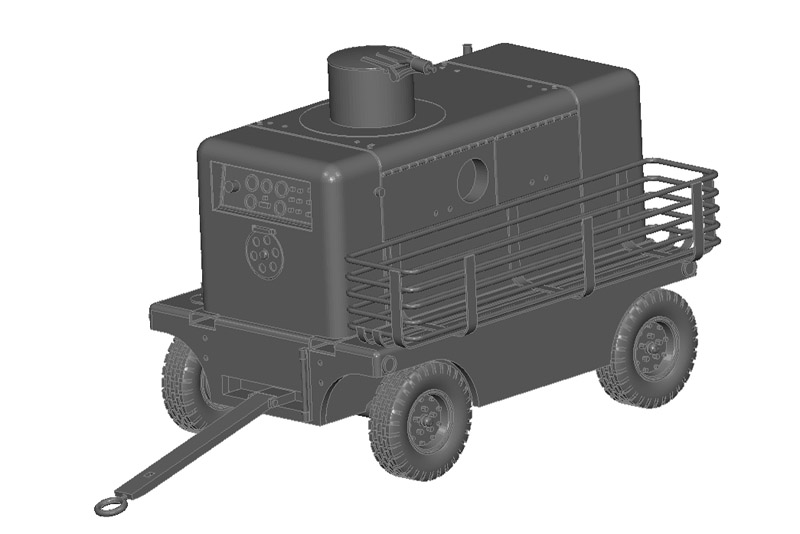

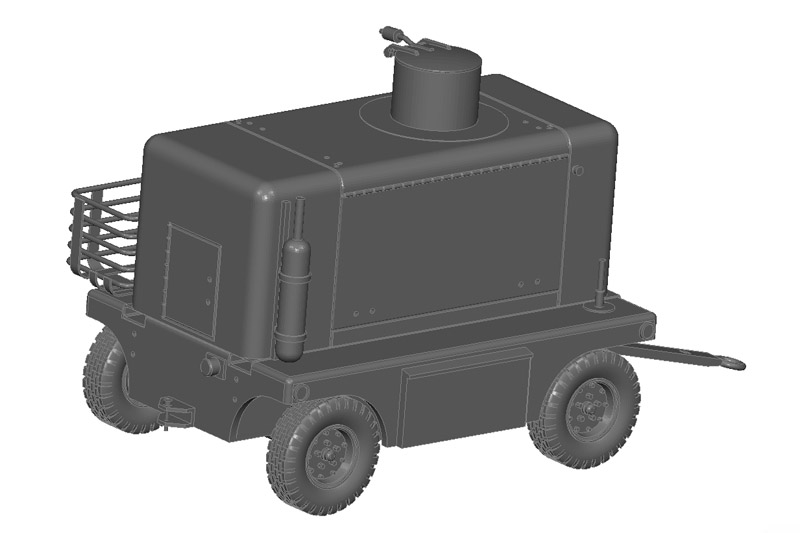

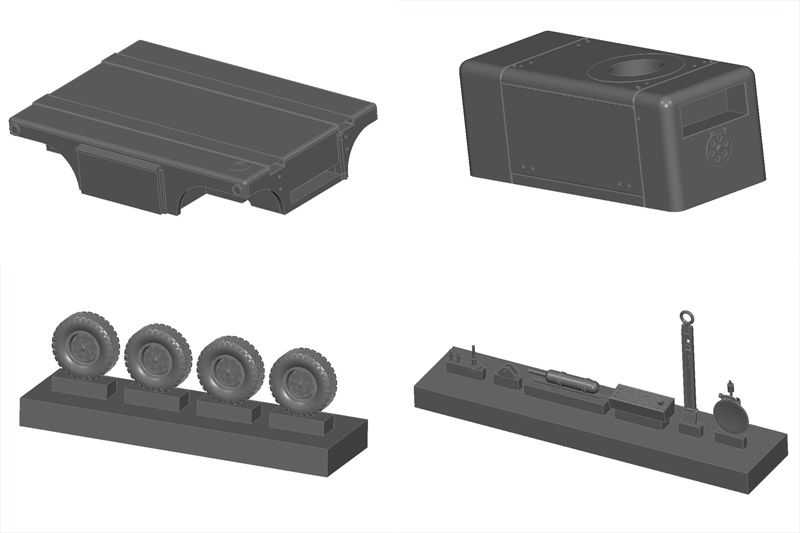

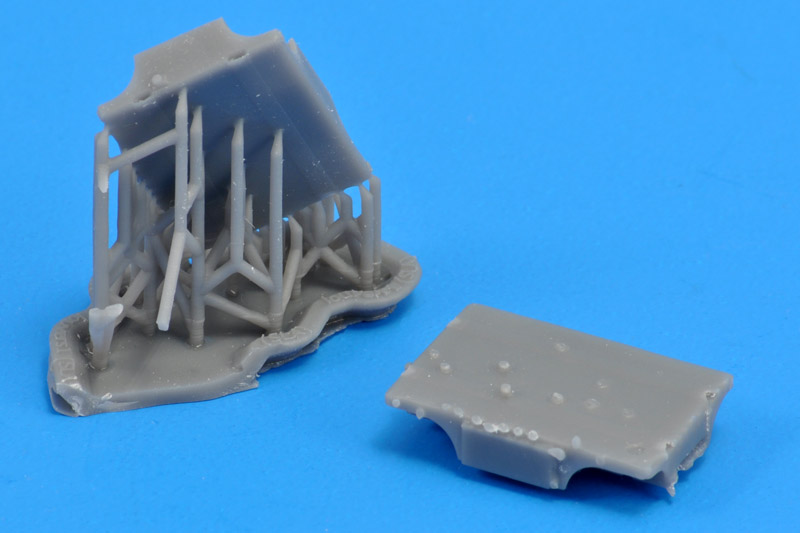

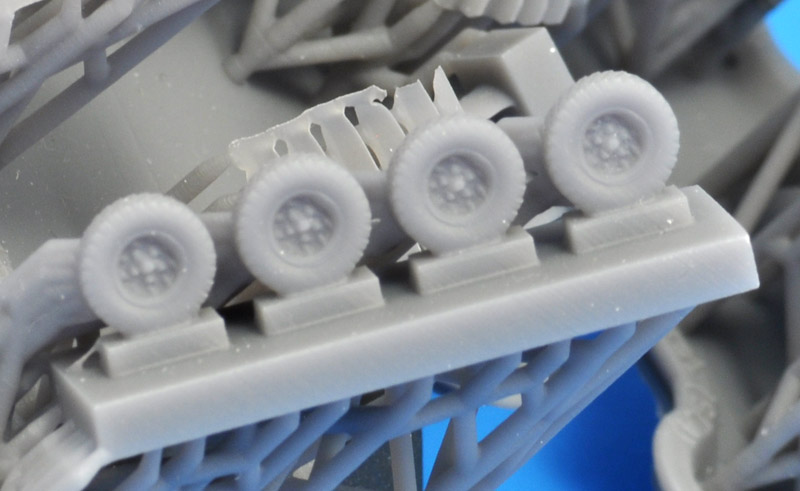

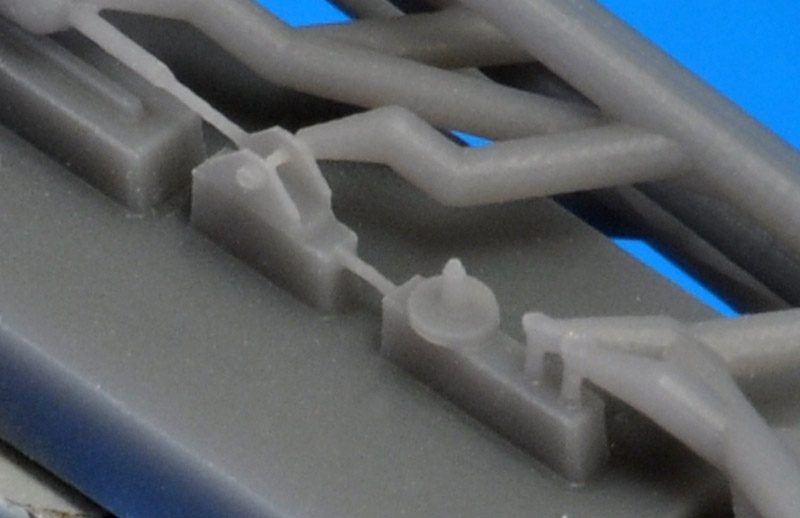

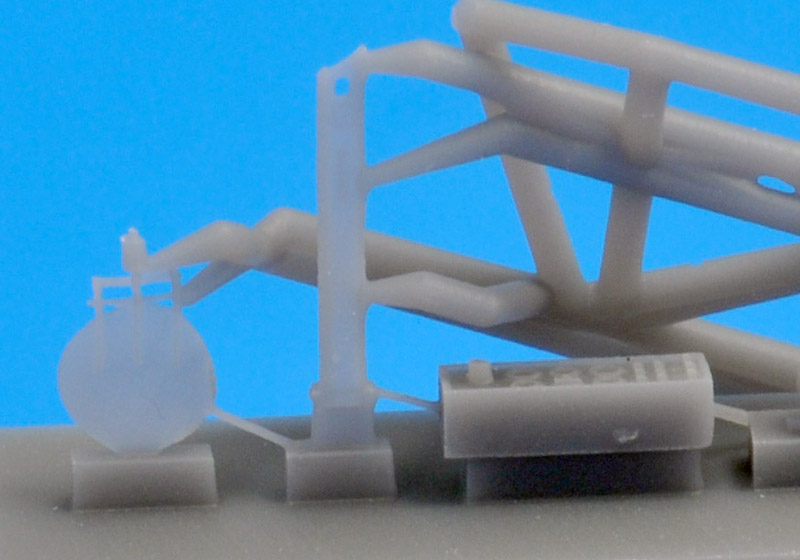

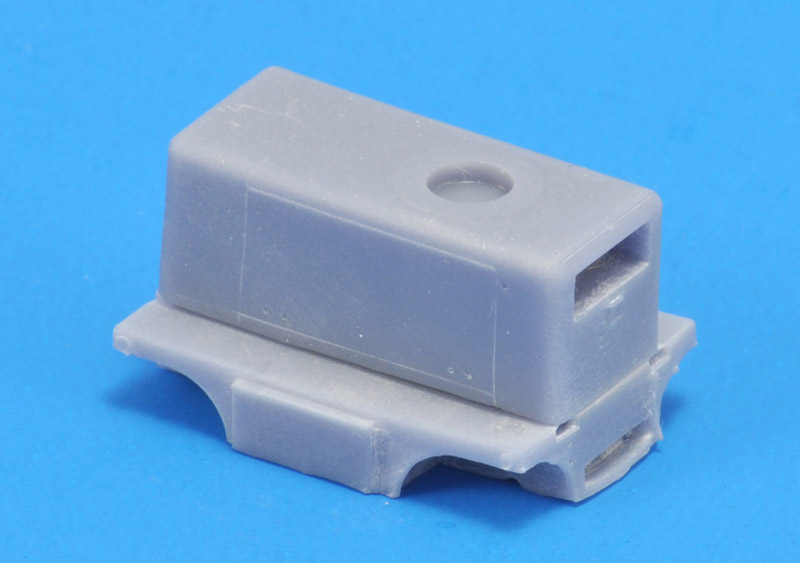

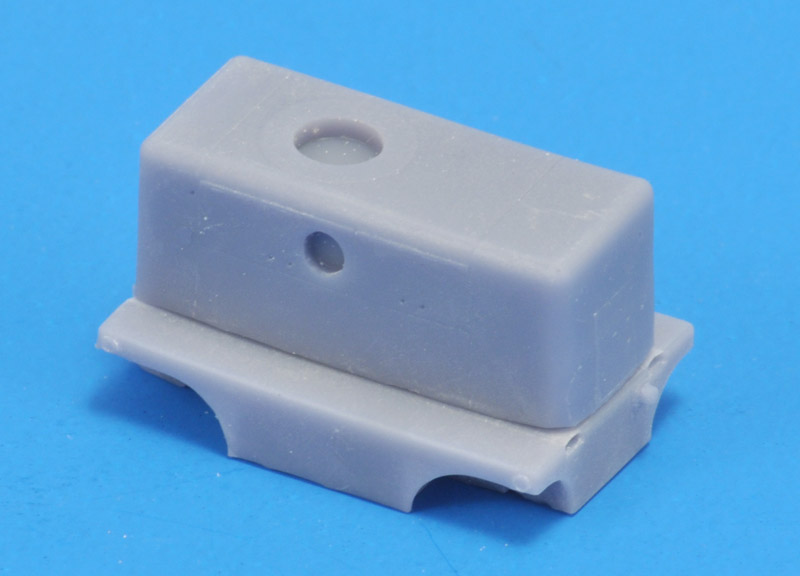

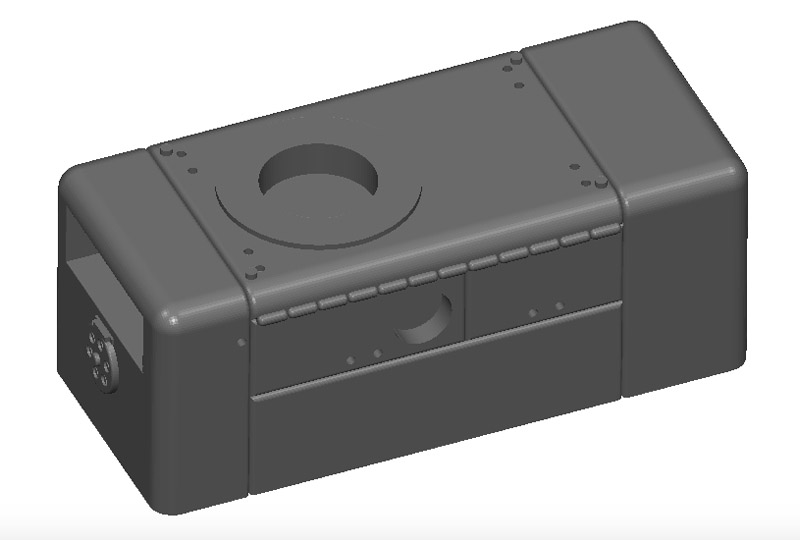

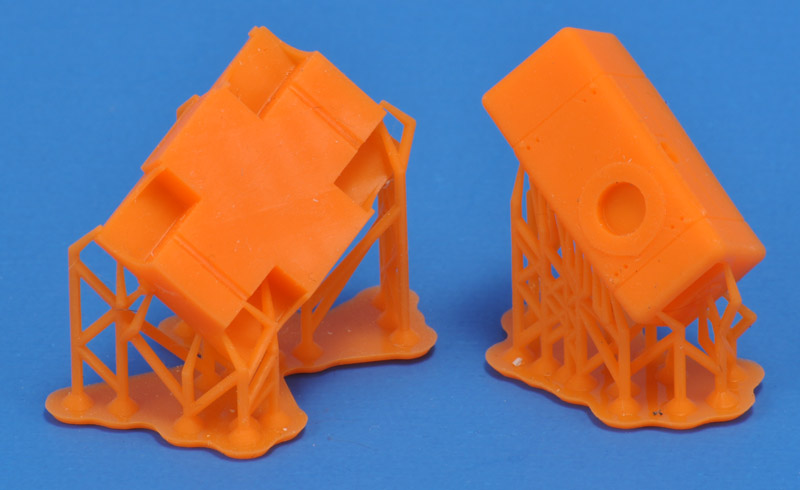

| I watched the starting of operational RNLAF F-104s from close-by on two occasions, and the noise of the little jet starter cart was very impressive. As far as I know, it was built by Fabrique Nationale (FN) and used a Boeing 502 turboshaft engine. This start cart type was used by the Royal Netherlands Air Force (for F-104 and NF-5), and in small number by the Belgian Air Force (for F-104). They were called 'turbo starter' in the RNLAF. I always wanted to scratch-build one, but I never found enough information, and it seems not a single one was preserved. But in 2020 I found many more photos, and I started building one, using 21st century scratch-building methods.

|