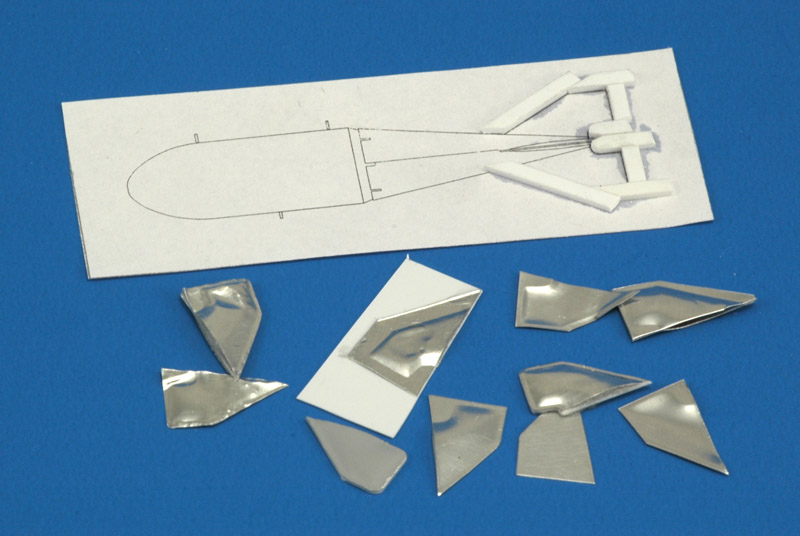

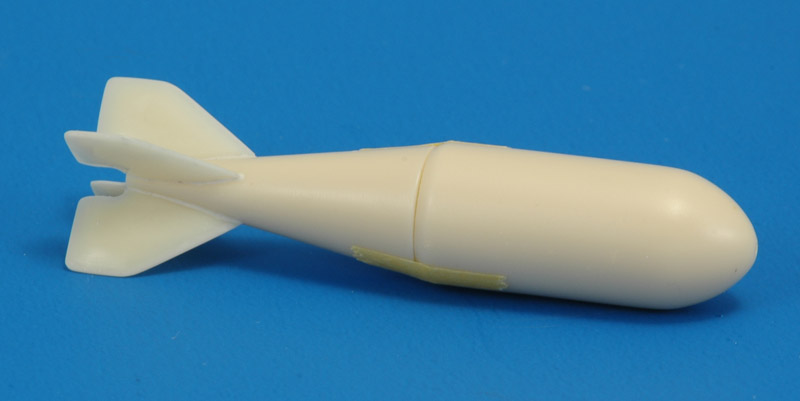

The bomb with a question mark is the 2000 lbs AN-M66. I thought it was used by RNLAF, but I'm no longer sure of that. I could have saved myself a ton of work, see below..

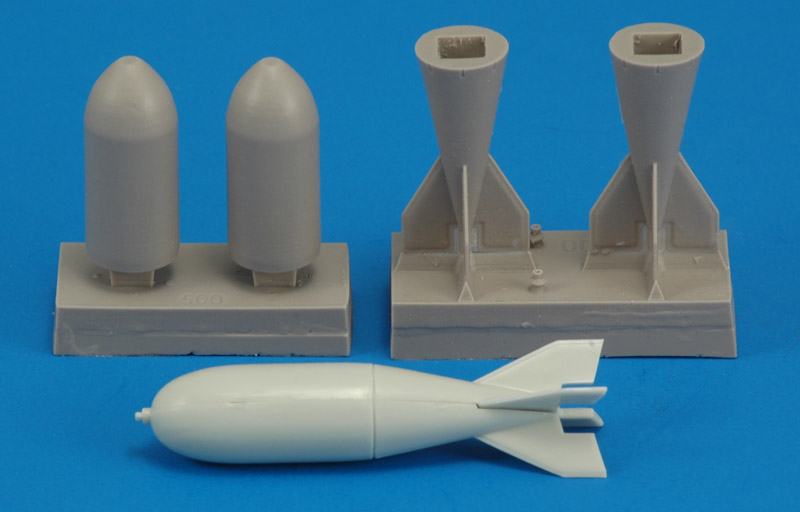

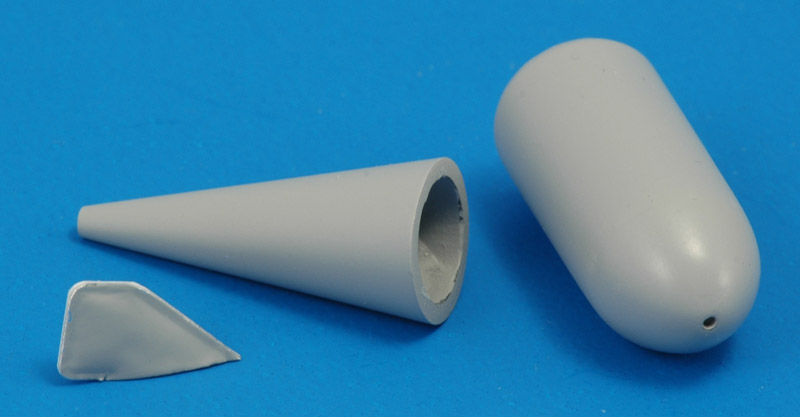

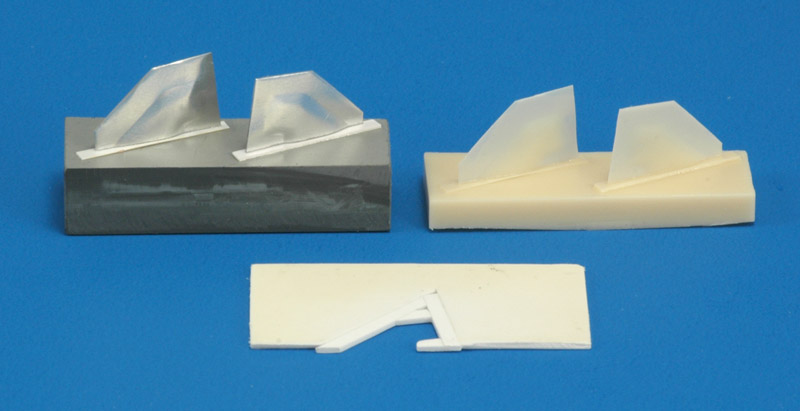

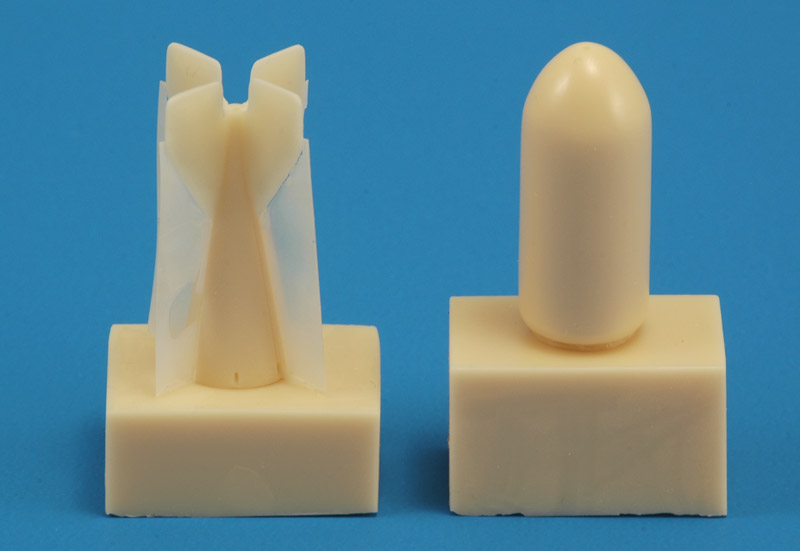

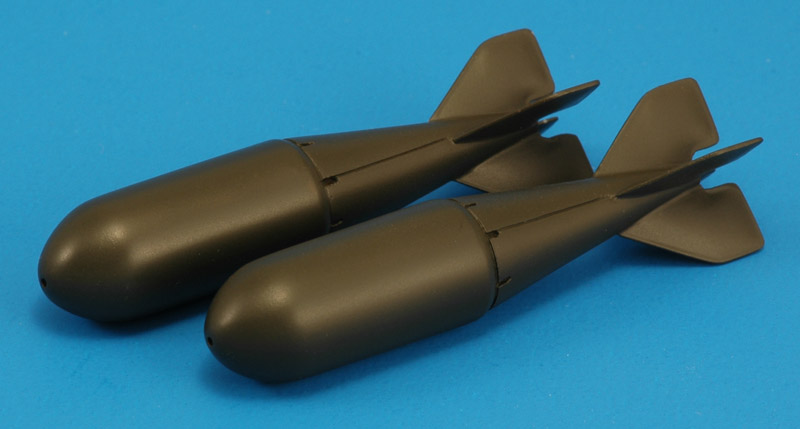

True Details (48505) and Attack Squadron (48030) have it in resin, but fitted with the WW2 style box tail section. To my disappointment both are quite similarly undersize, around 10%. True Details' diameter is 11.2 mm, 91% of the real value (or 83% in cross section area), the length is 35.3 mm, 93% of the real value. Attack Squadron diameter is 11.3 mm, 92% of the real value (or 84% in cross section area), the length is 33.9 mm, 89% of the real value. Again the source of the reference data is the combined TM 9-1325-200 (Army) / TO 11-28 (Air Force) 'Bombs and bomb components' from 1966, page 2-25.

|

|