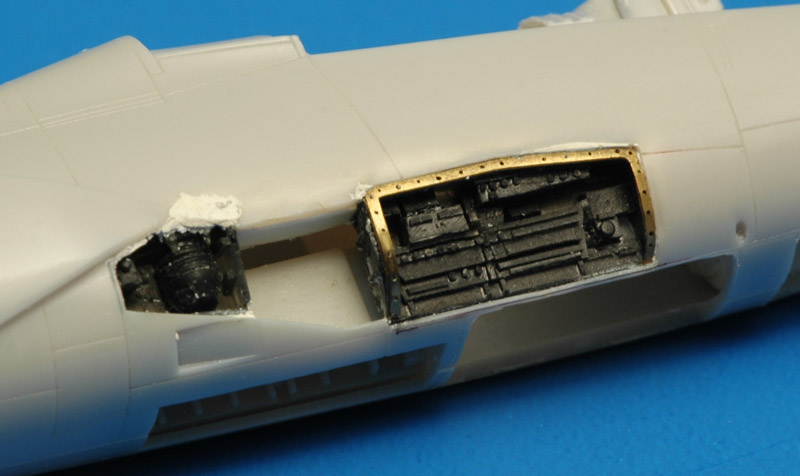

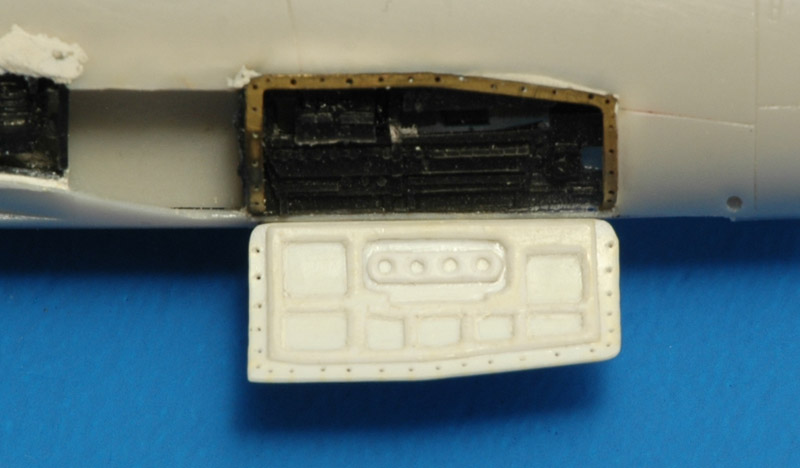

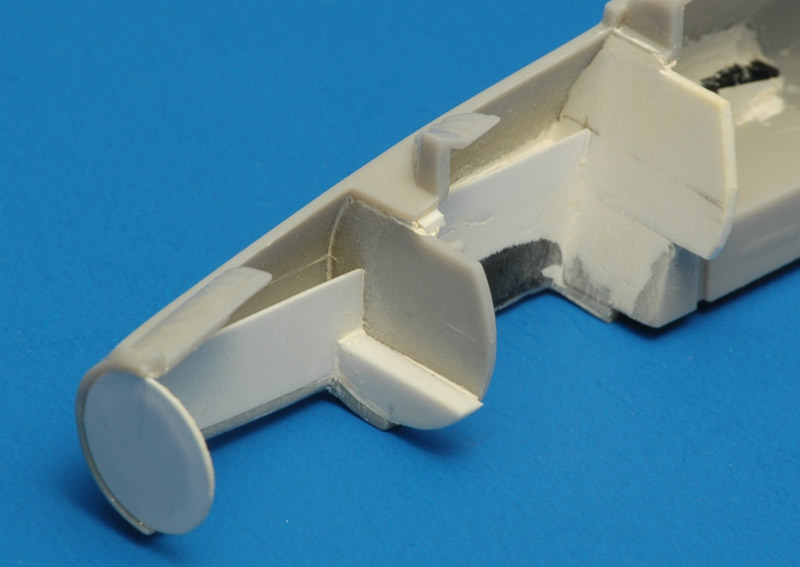

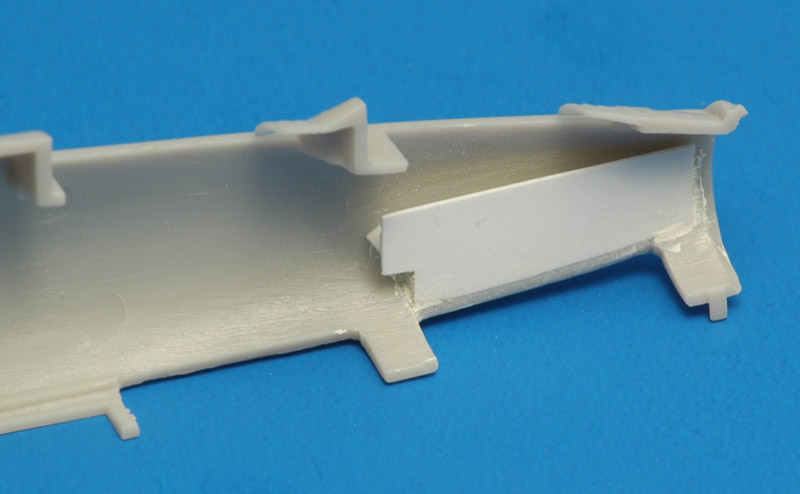

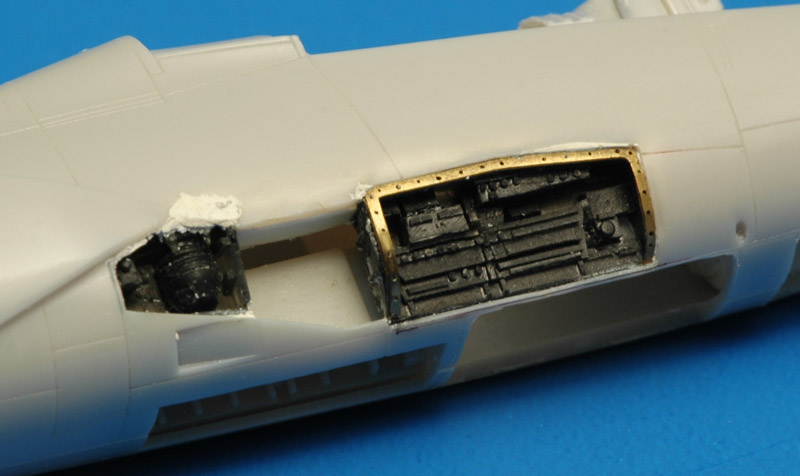

I started with the three hatches on the forward fuselage (from front to rear: avionics, ram air turbine, liquid oxygen). My inexperience with removing hatches showed clearly when I opened them. I had scraped the interior very thin, and then tried to cut out the hatches, attempting to get them out clean, so I could use them again. Very wrong. The thin plastic deformed severely during my cutting attempts, and both the fuselage and the hatches were damaged. With 20/20 hindsight I would have taken my losses with the hatches, and would have started with drilling holes in the hatches, followed by lots of cutting and filing until the opening was right. Then the edges could be thinned.

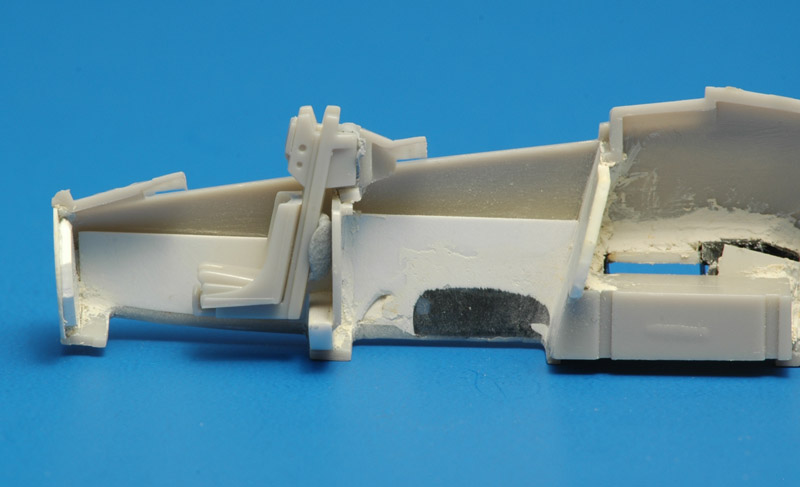

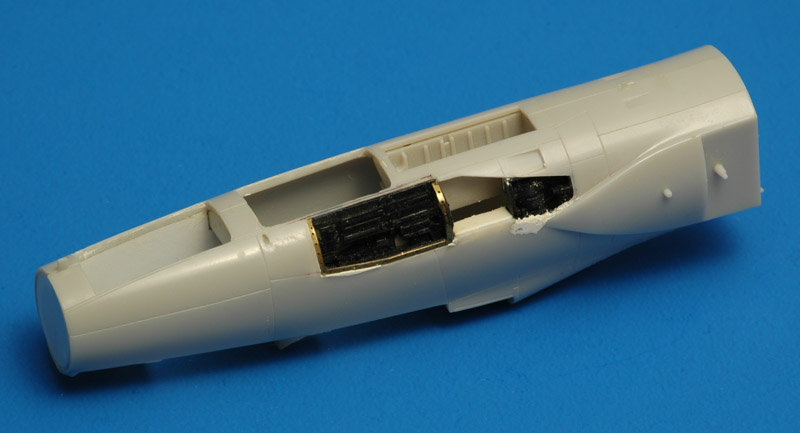

Anyway, I could repair the damage reasonable well, and started installing the Verlinden hatch interior. Wrong. It didn't fit. The compartments are stepped, and the resin part does not have the proper steps. Radical solution: I cast a copy of the part, cut out the middle section, and installed the forward and aft ends. The middle one is basically a square box without detailing, so this is the best way around the problem. The photo-etch part around the forward compartment didn't fit either, and had to be modified. I poked through the thin edge of the aft compartment, and roughly repaired it with Milliput.

|

|