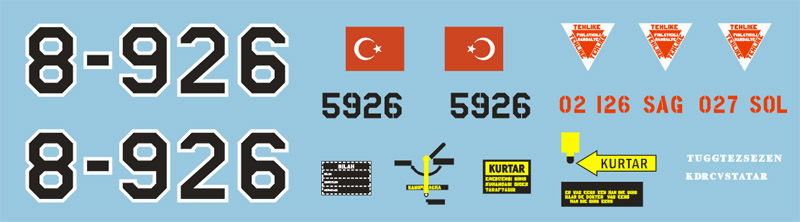

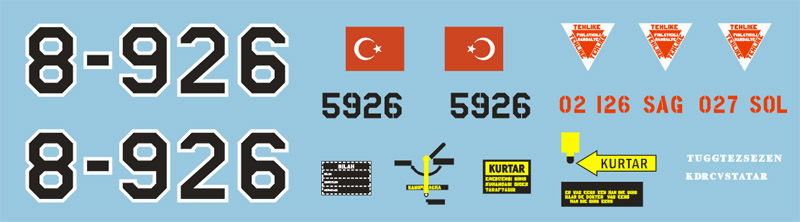

| Working from my slides of 5926/8-926 of 181 Filo / 8 AHU, I designed the following decals. The white edging on the code number '8-926' was shifted on the real aircraft, but replicating that in the decal would probably only result in comments about badly printed decals, so I left that out with some regret. Starting with Amarillo USAF, the '2', '6' and '9' were all slightly changed. I checked the text of the smaller stencils with a Turkish NF-5B at an airshow, and I think most spelling errors have now been eliminated. Fellow modeler Kursad A. wrote to explain that 'TUGG TEZSEZEN' stands for 'Tuggeneral (Brigadier General) Tezsezen', back then the Balikesir base commander, and later the general manager of TUSAS Aerospace Industries. 'KD CVS TATAR' is short for 'Kidemli Cavus (Sergeant-Major) Tatar', likely the crew chief of the aircraft. Unfortunately I (again) made the mistake to design decals that are too small to read. For example, the smaller markings on the 'SILAH' panel are only 0.14 mm high. The larger 'SILAH' marking is 0.31 mm, which is just readable. But at least the decals will look realistic I think.

|

|