I first tried to clean the splinter in an ultrasonic cleaner, but to my surprise, almost nothing came off.

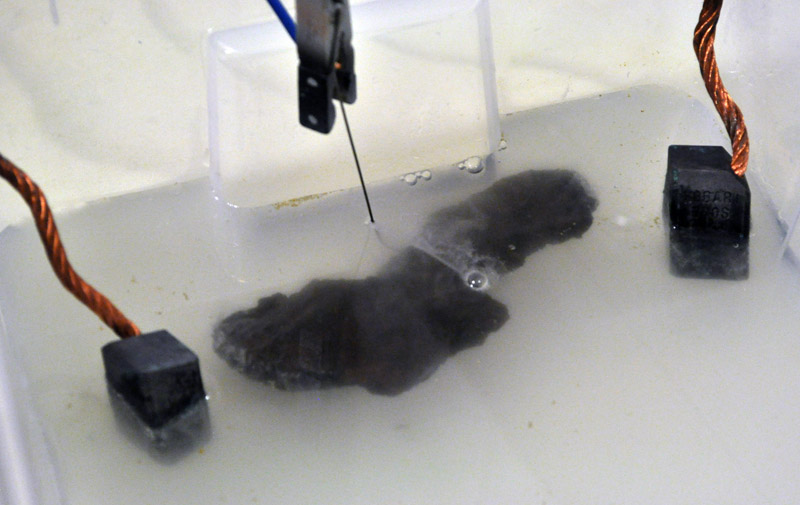

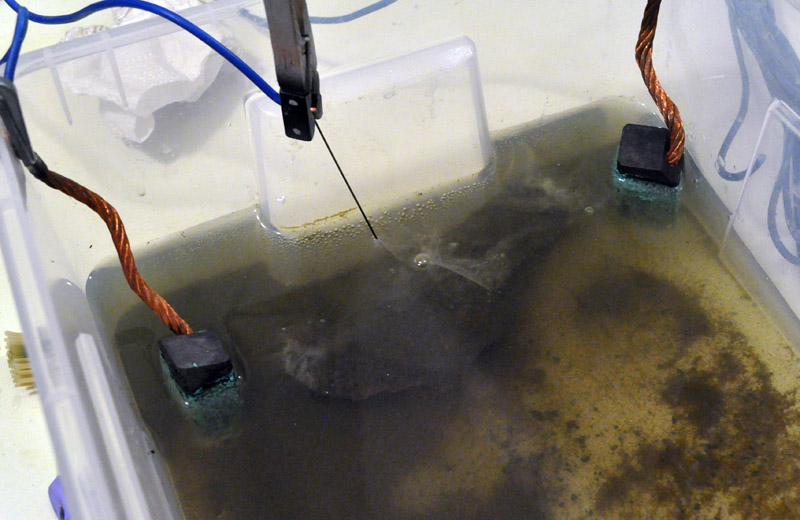

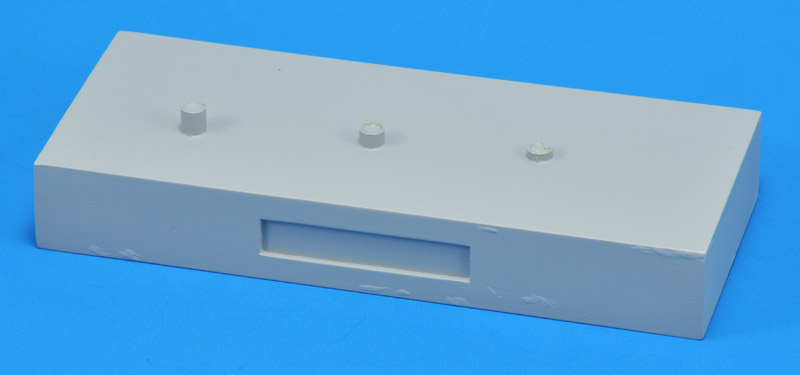

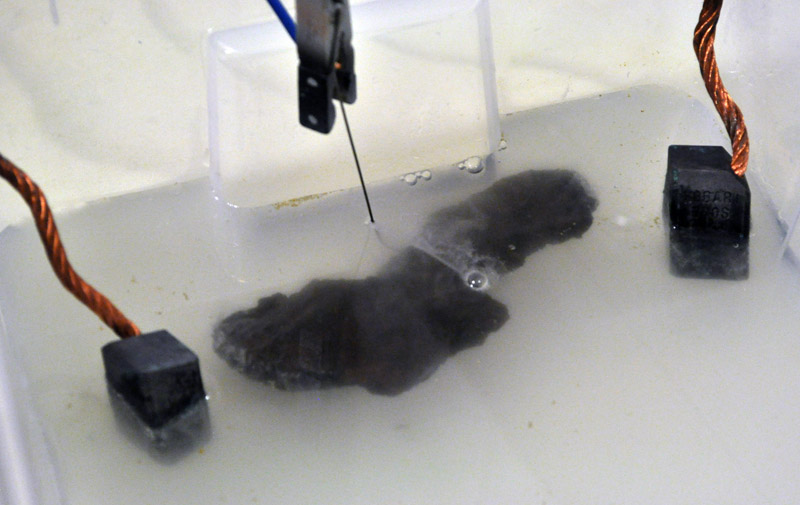

Secondly, I tried electrolysis, as seen on YouTube. Here's my initial set-up. I wanted to avoid creating the rust sludge that comes with the use of steel positive electrodes, so I sourced two carbon brushes from a large electric motor.

I used an old toy train transformer, that on average gave 12 volts and 0.8 amps, 10 Watts power, while using 18-19 Watts. In most YouTube videos, more power is used. Maybe I could have used a laptop power supply, they are often 19 volts and a few amps.

|

|