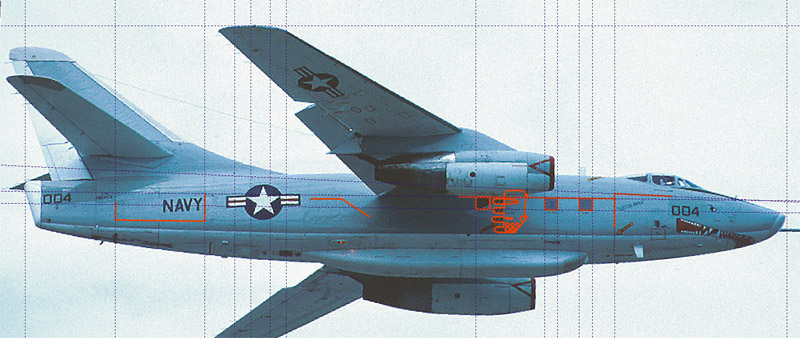

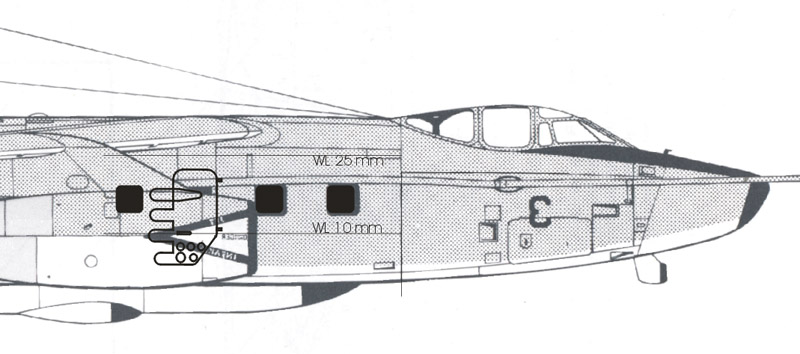

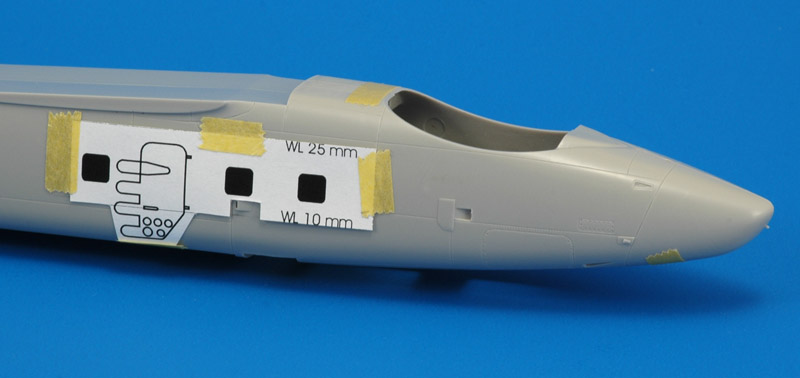

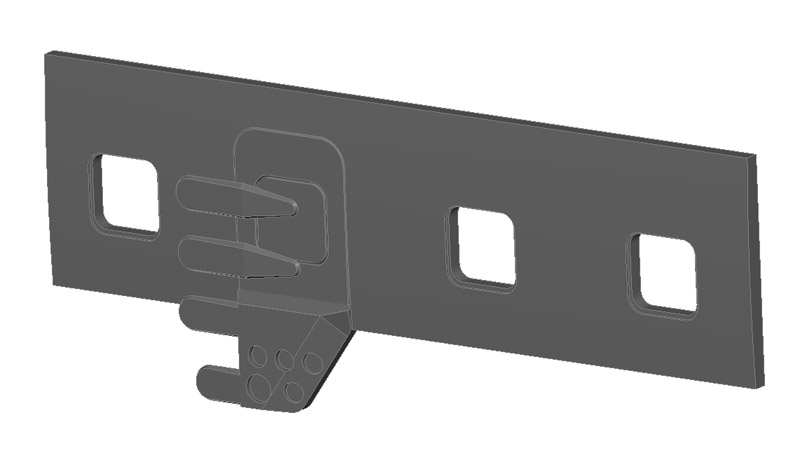

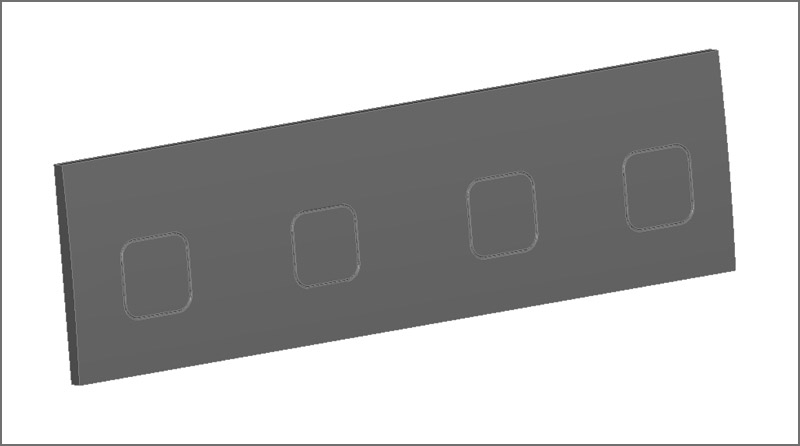

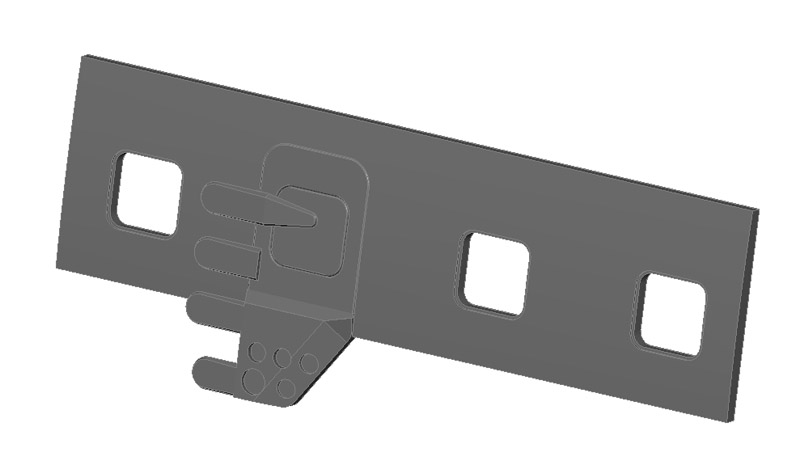

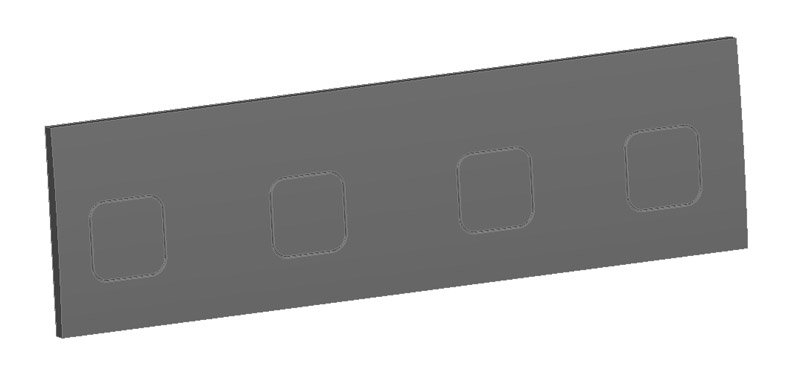

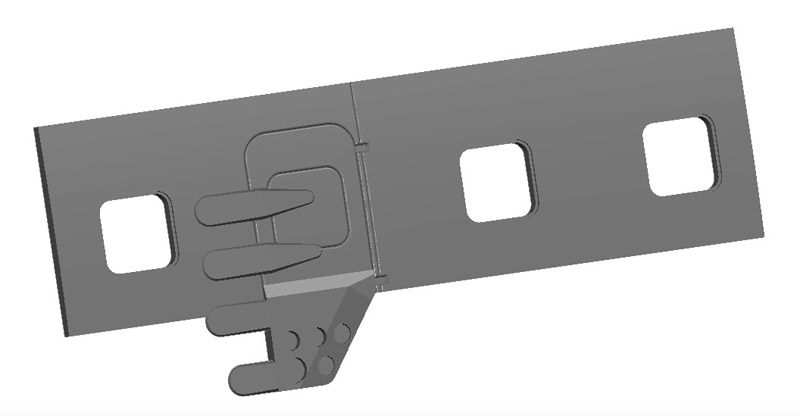

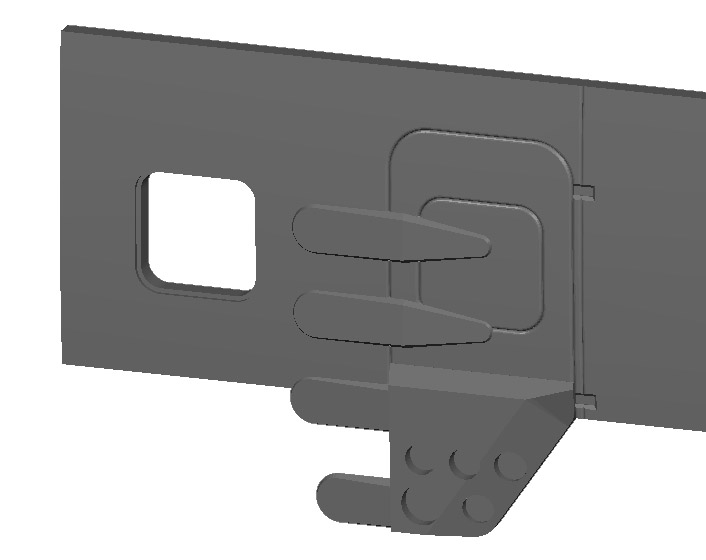

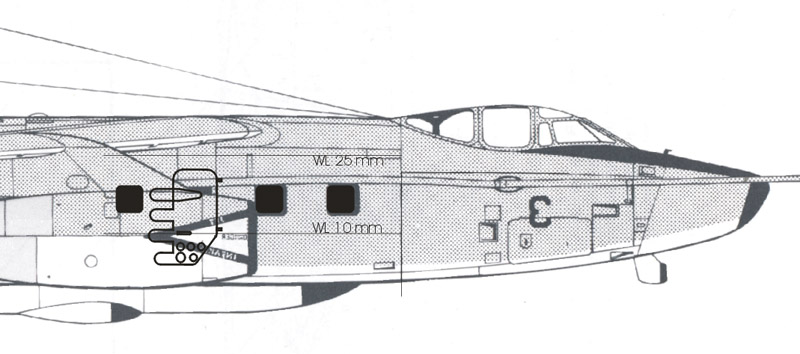

| Next I scaled the drawing from Aerograph page 80 to 1/72 scale, and copied the above on it. I calculated that the aircraft in the above photo had a 25 degrees 'bank' angle, leading to a cos(25)=0.906 shortening of the vertical dimensions. Therefore, I compensated by a 10% vertical enlargement. This gave me almost perfectly square windows, always a nice check for your work.

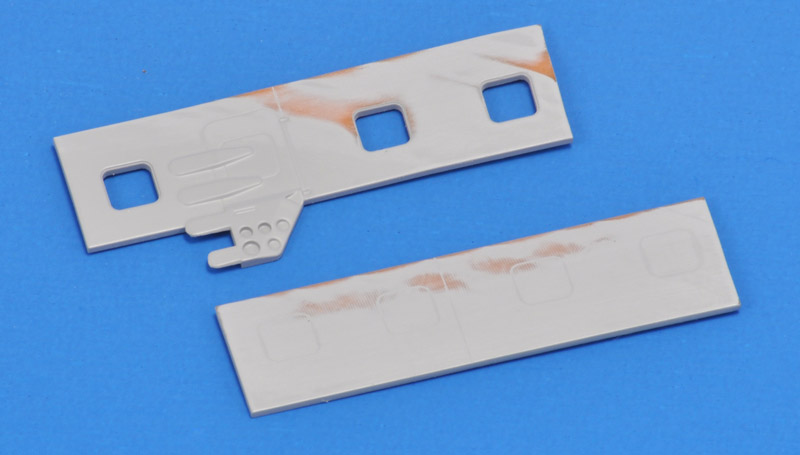

'My' windows were a bit smaller than those of the drawing, but the positions agree fairly well. I calculated a size of 14.7" and rounded it off to 15". Likewise, I calculated that the rounded corners were 19% of the width/heigth, and rounded that off to 20%, or 3".

|