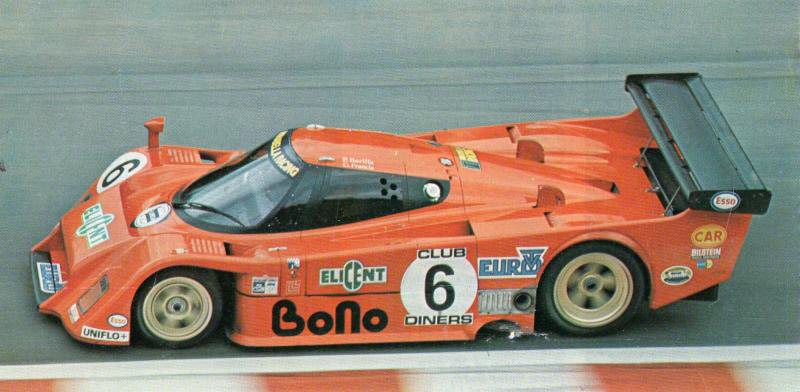

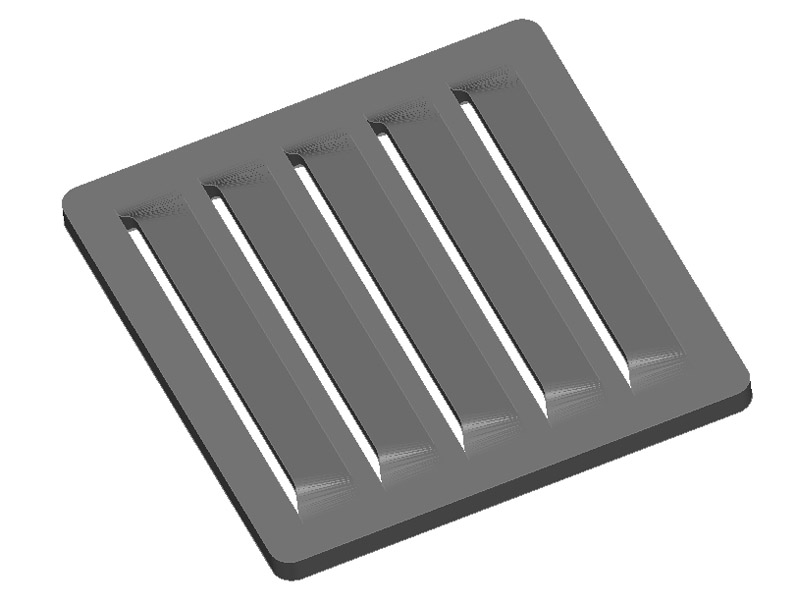

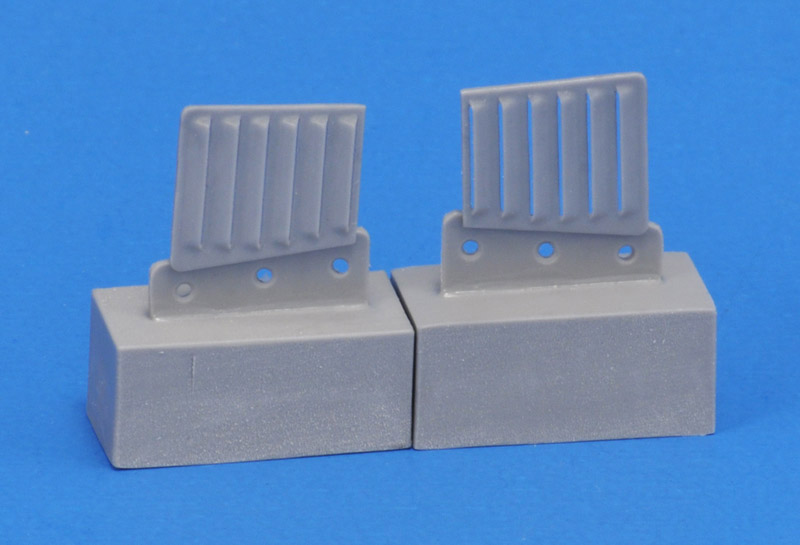

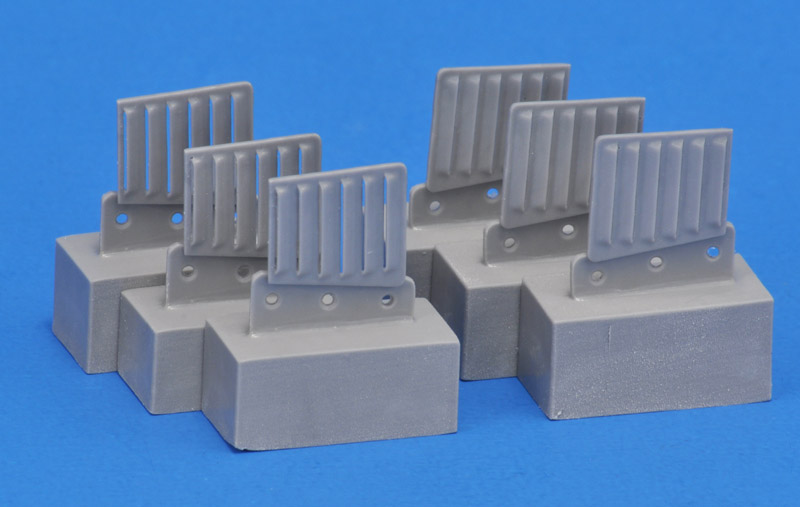

1/24 Lancia LC2 front wheel louvers

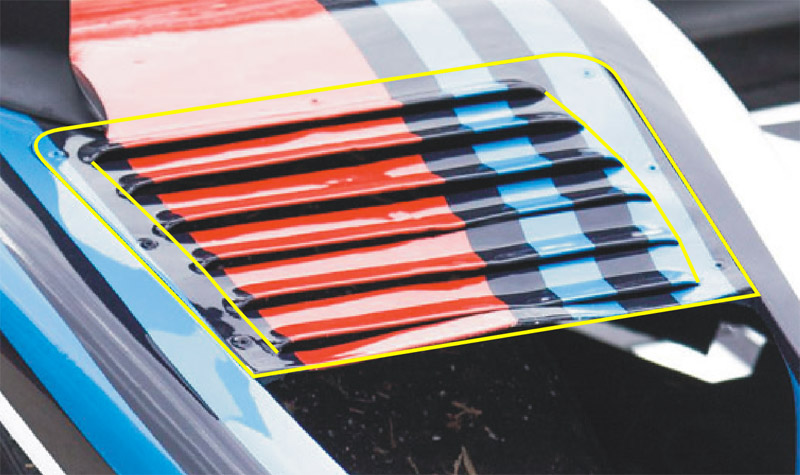

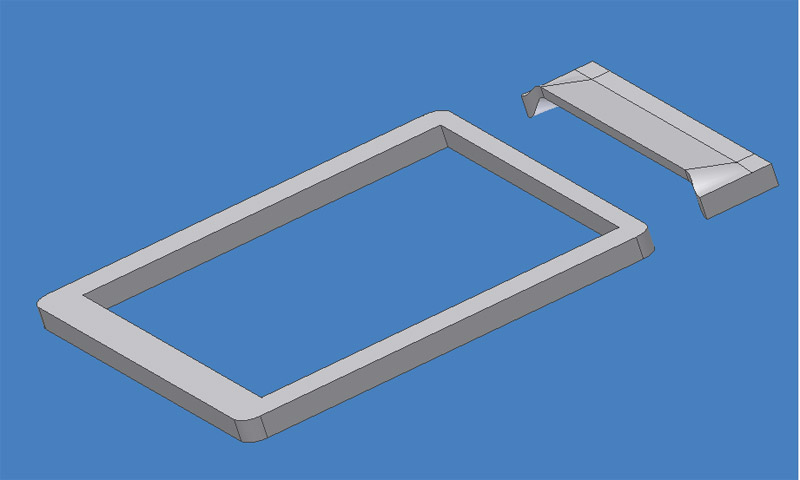

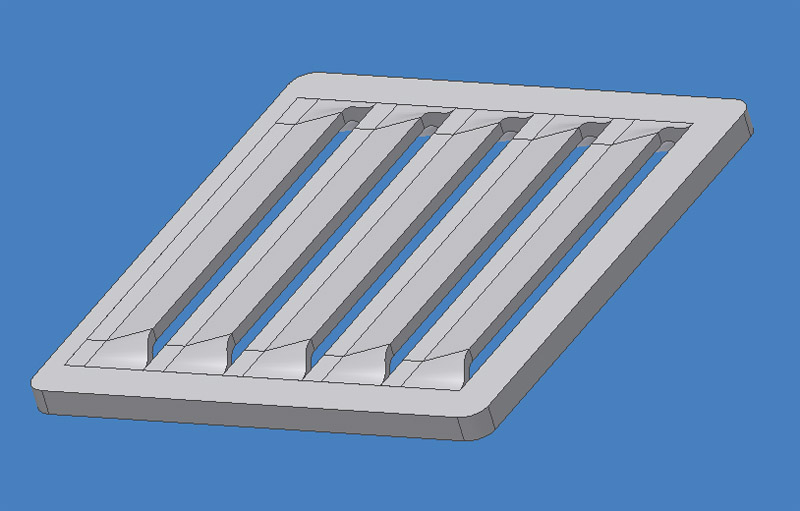

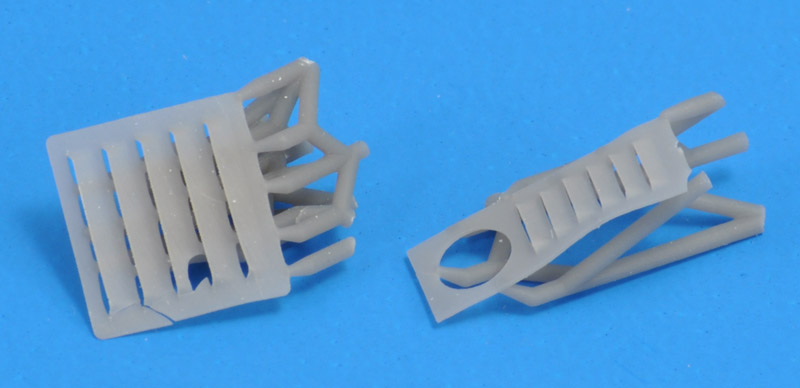

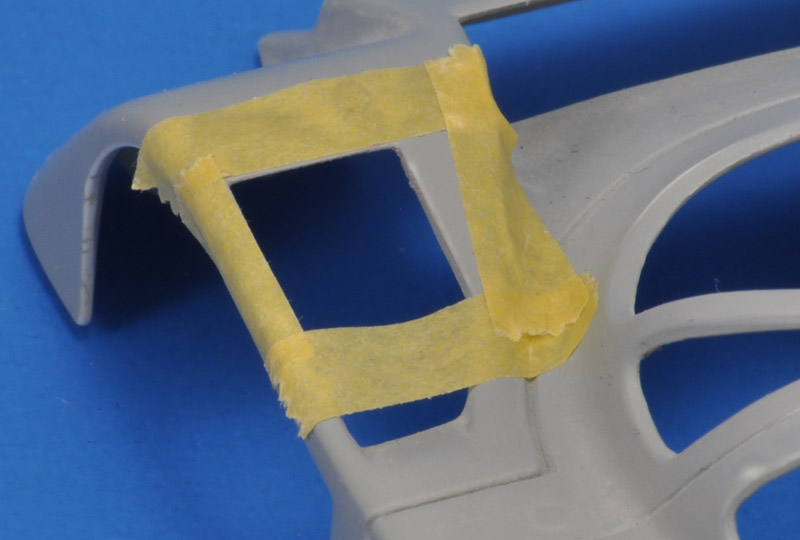

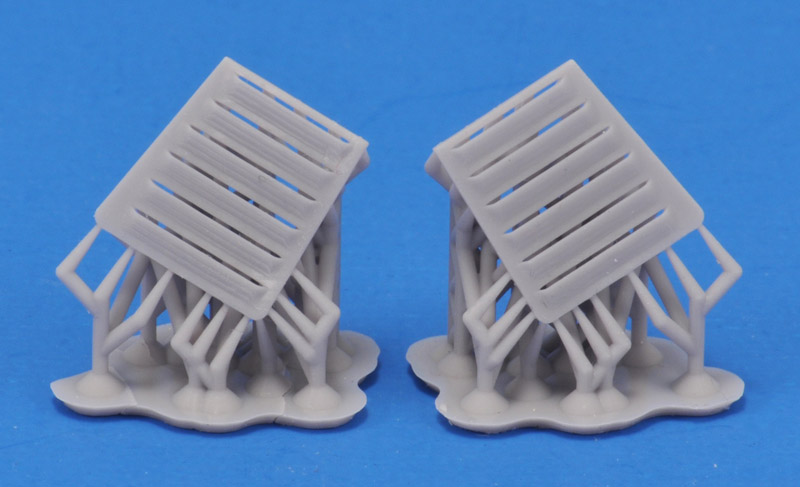

| The Protar 1/24 Lancia LC2 that I'm building is a primitive kit, with many details that cry for improvement. I decided to take the louver panels over the front wheels as a good subject to try to design and print new parts for. |