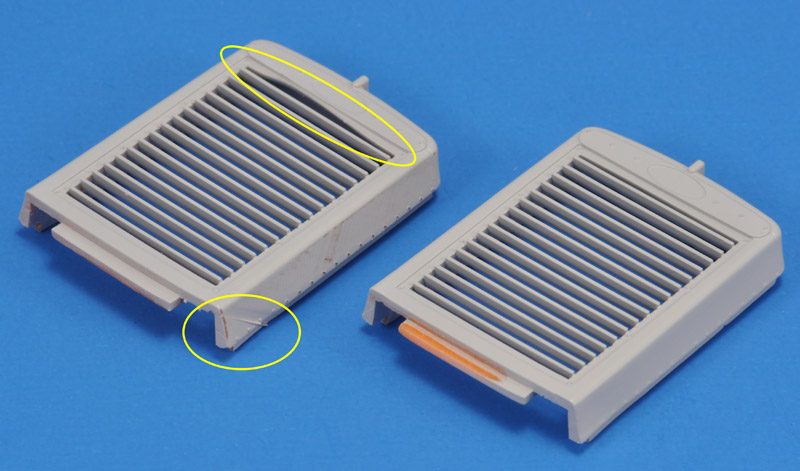

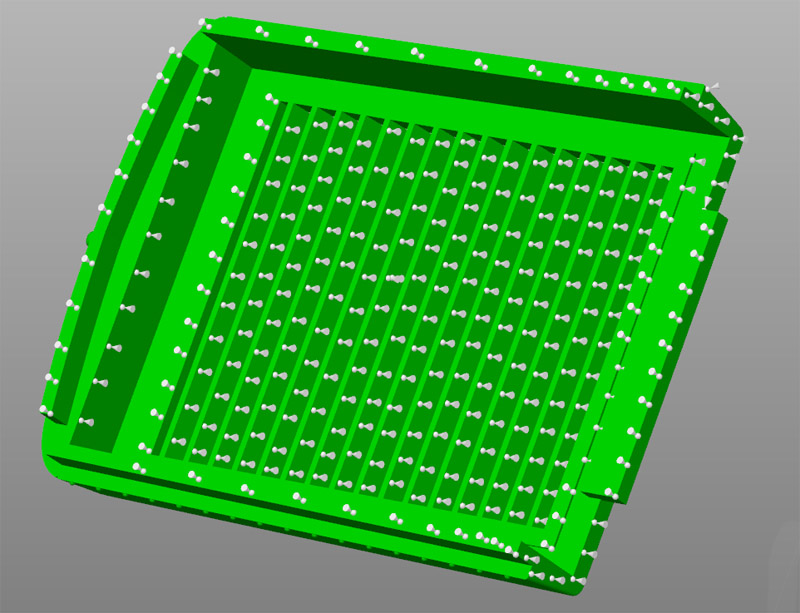

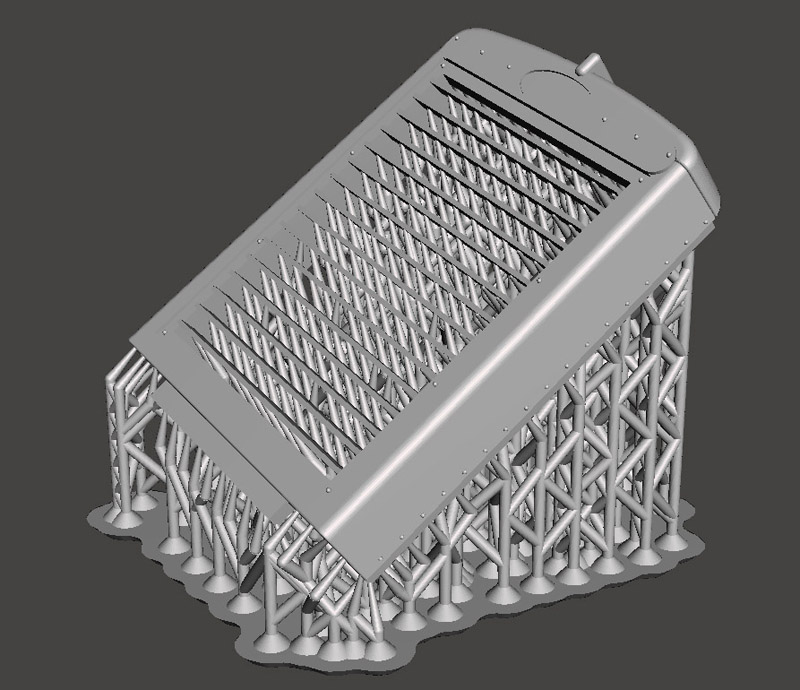

1/25 'Duel' Peterbilt 281 'needle nose' grille

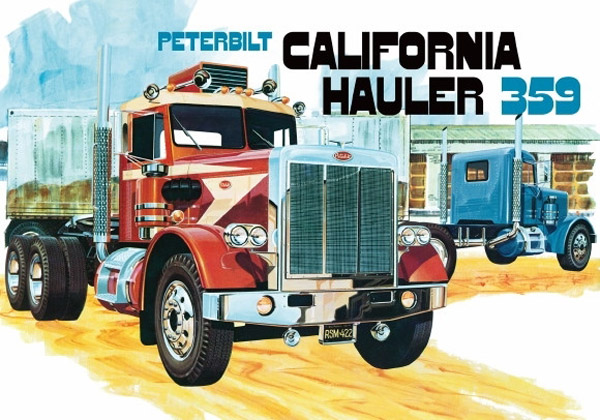

| The movie 'Duel' made an impression when I saw it as a child, just like 'Convoy' did in a different way. 40 years later, I have plans to build two US trucks: the 'Duel' Peterbilt 281 and the 'Convoy' Mack R700. For the Duel truck, you generally start with the AMT Peterbilt 359. It's a complicated project: cab, hood, grille, wheels, tires, engine, axles have to be changed. I started work on the front wheels and the cabin's front windows, followed by the 'needle nose' grille. |