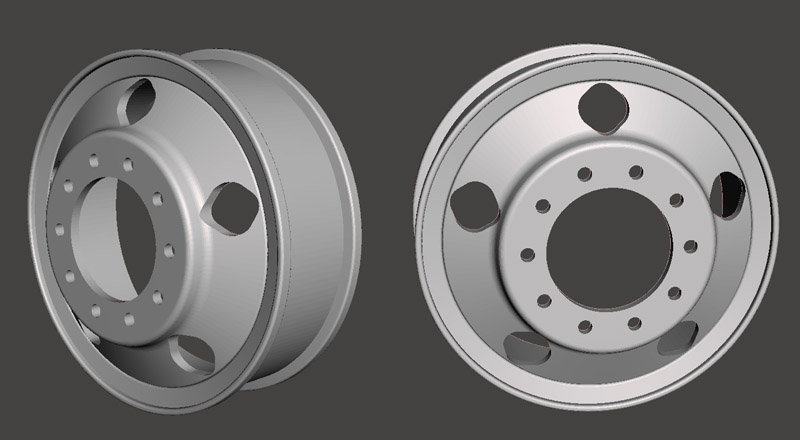

Apparently wheels for the Duel truck were made by 'Griffen Designs' in resin around 2009, but they no longer active (see The Duel Truck, who makes a kit). Also mentioned are the front wheels of an AMT fire truck, likely the American-LaFrance Custom Pumper / Ladder Chief / Aero Chief series of models. What I found showed five-hole wheels, but the holes were D-shaped, and I could not find the size. Lastly, the Moluminum Tyrone Truck Mate Wheels. Also a five-holer, but with elliptical holes, and again I could not find the size. 'DoubleTake' is also mentioned, but has closed shop.

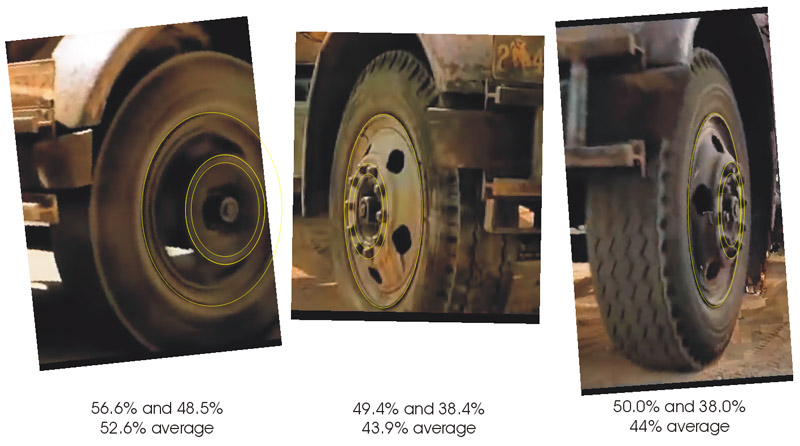

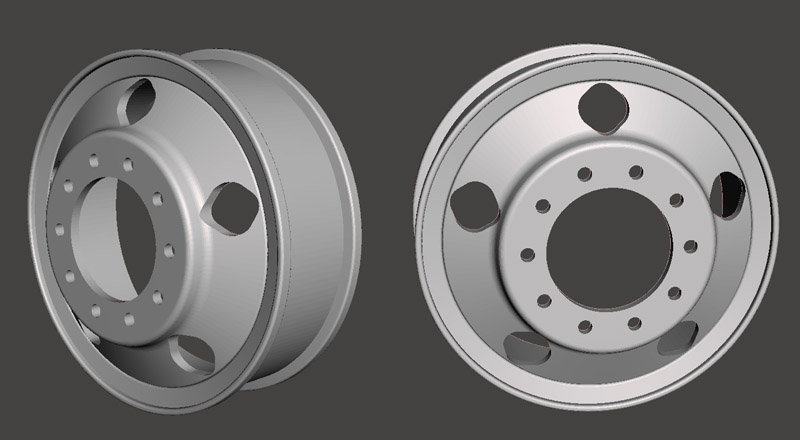

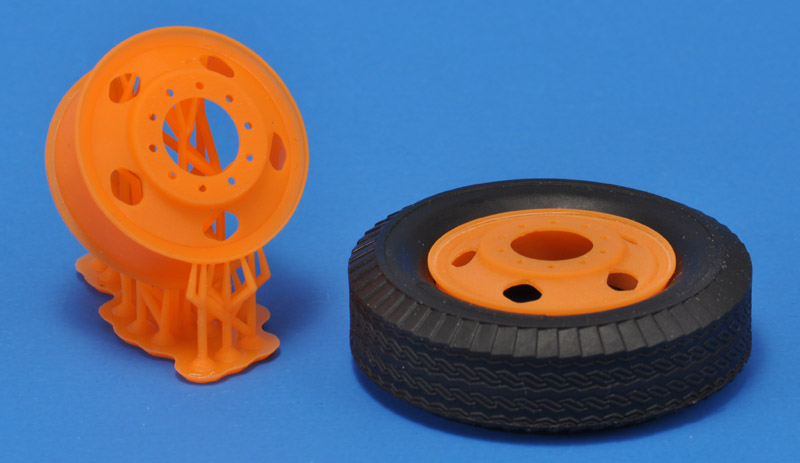

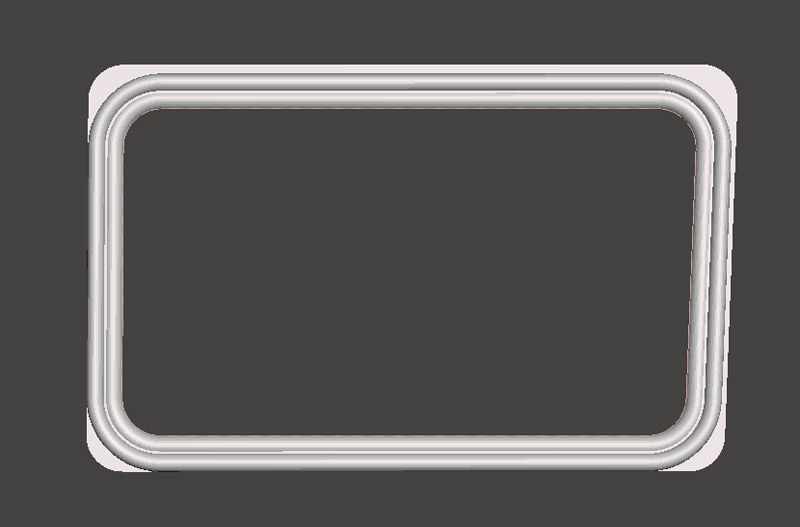

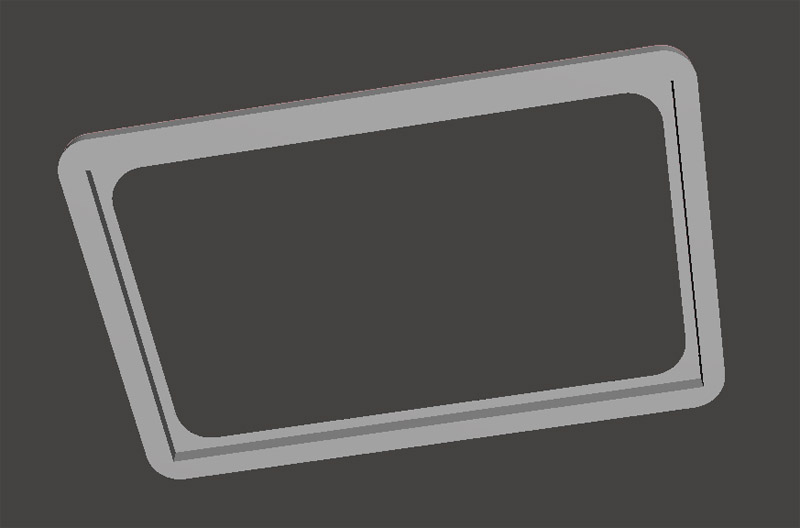

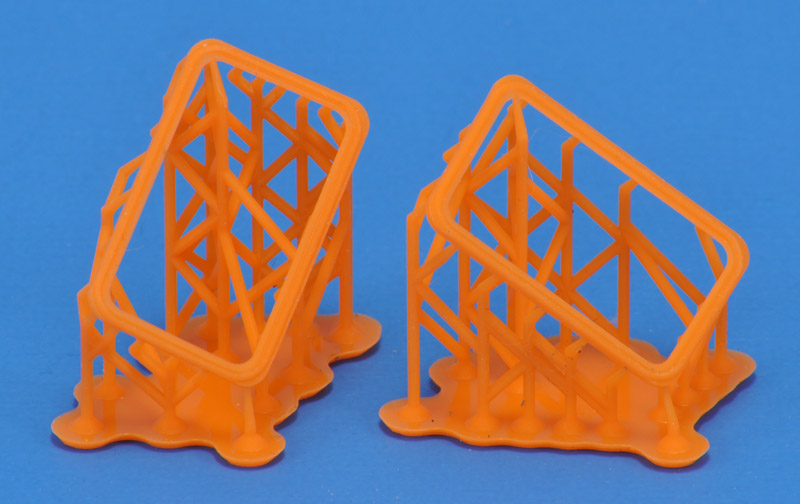

I concluded it was easier to have my own wheels printed, than find and order them from the USA. Here's my first version of the front wheel in 3D. It needs to be refined. All dimensions in 'axle direction' were guesstimated from the photos, I don't have a way to measure them.

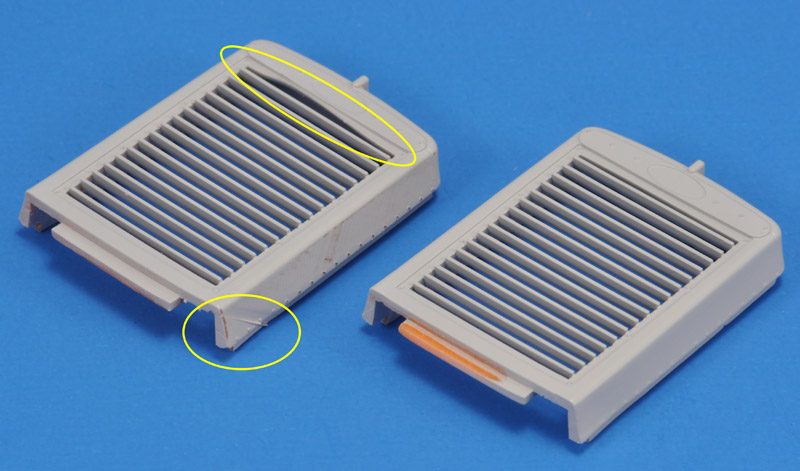

Note to myself: the front wheels have different colors.

|

|