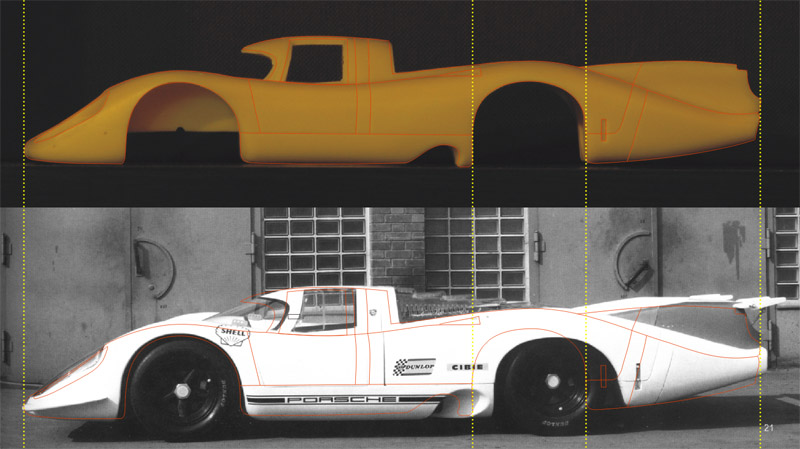

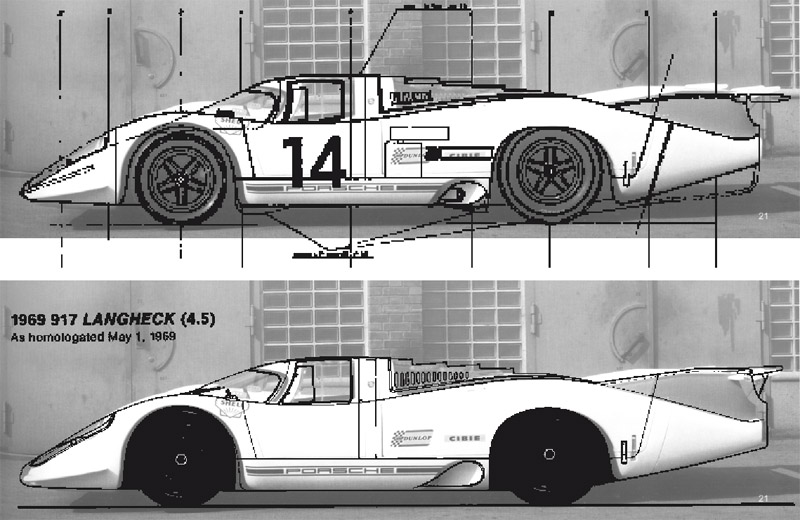

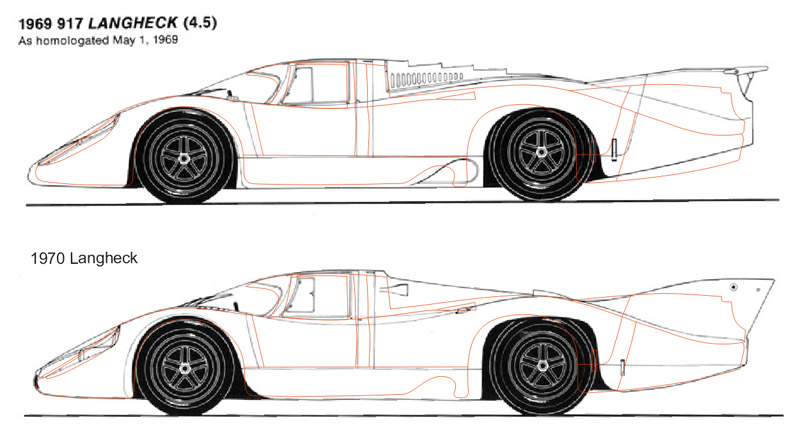

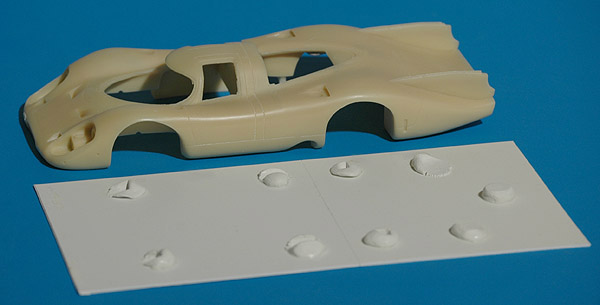

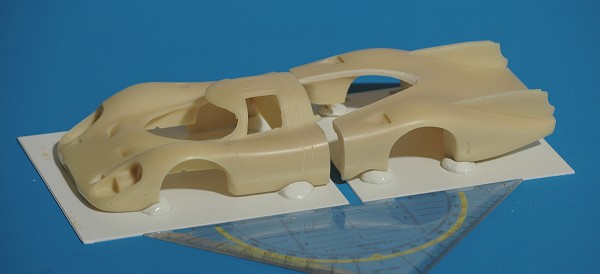

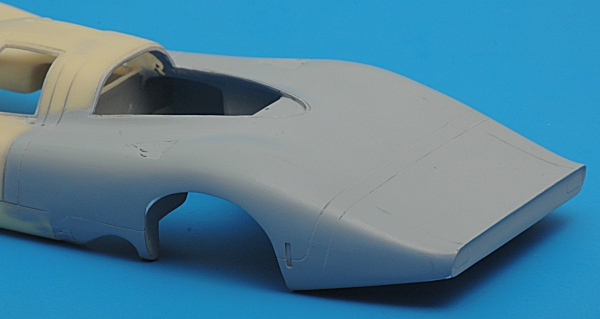

The tail was cut from inside the wheel wells, until it could hinge on the top side. Using the jig made earlier, I rotated the tail section so its rear was 2 mm higher, and fixed it in place with plastic card and superglue. The fins were cut off using a JLC razor saw, for modification later.

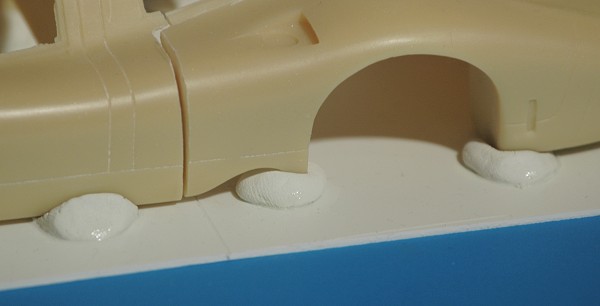

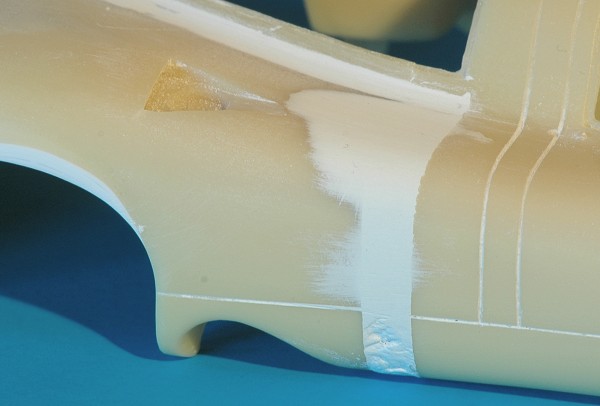

Next I removed a section of 4 mm for the rear side of the tail, and reattached the end piece with tail lights. The joint still needs to be puttied. The lower side of the tail was also reshaped, changing the 1970 curvature to a near straight 1969 line (compare with next photo).

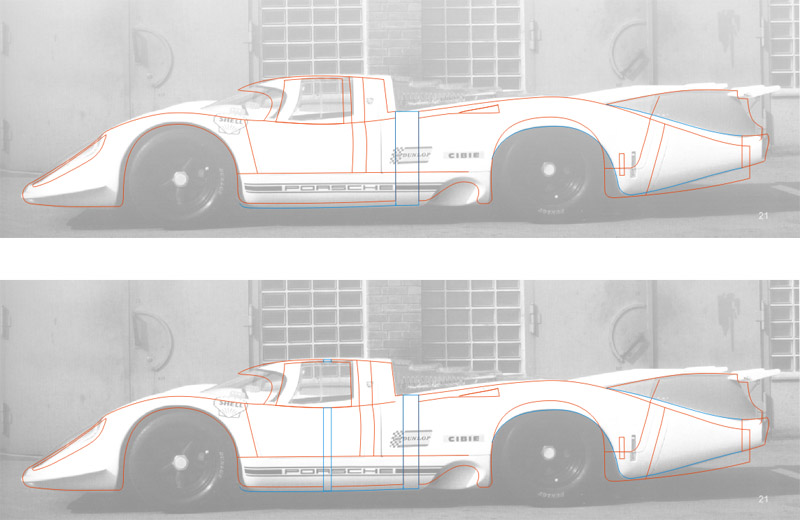

I also modified the wheel opening. I started with slanting the rear side of the opening, then I glued a number of plastic card strips inside the opening. I taped the the line drawings shown above to the body, and then sanded the wheel opening to an accurate shape.

|

|