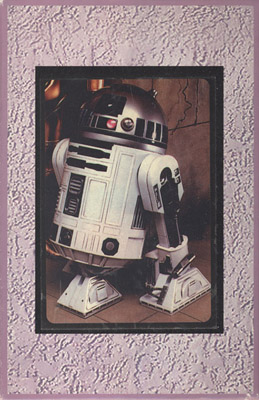

Sol or Elfin (?) 1/6 R2-D2

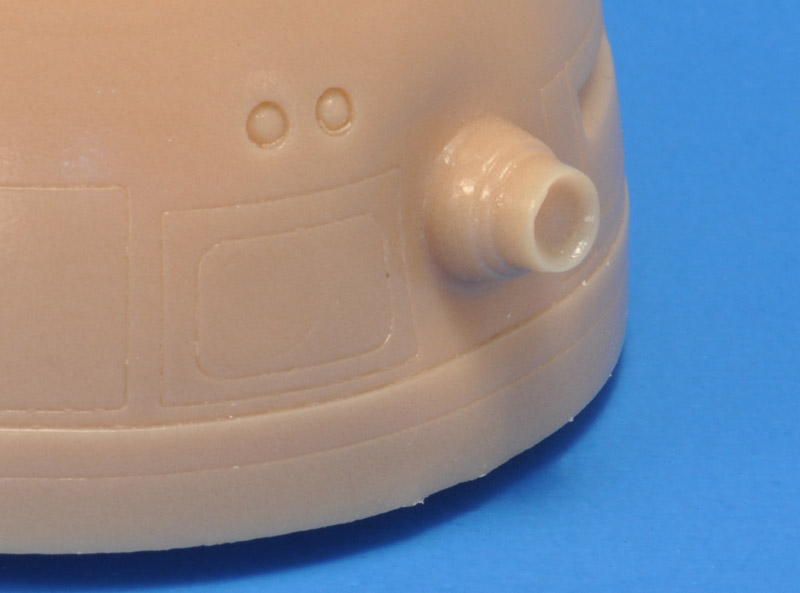

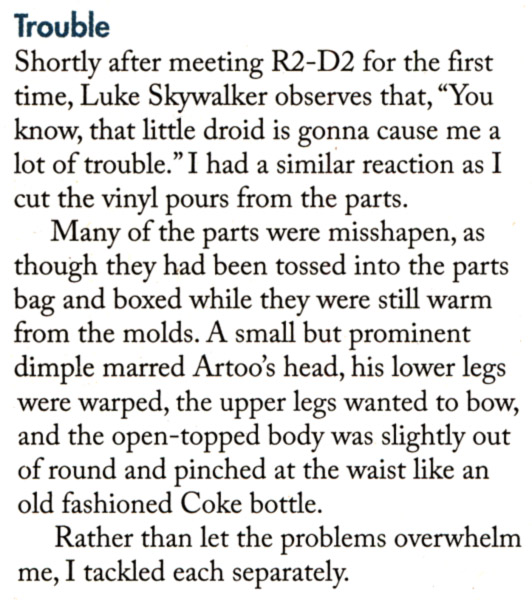

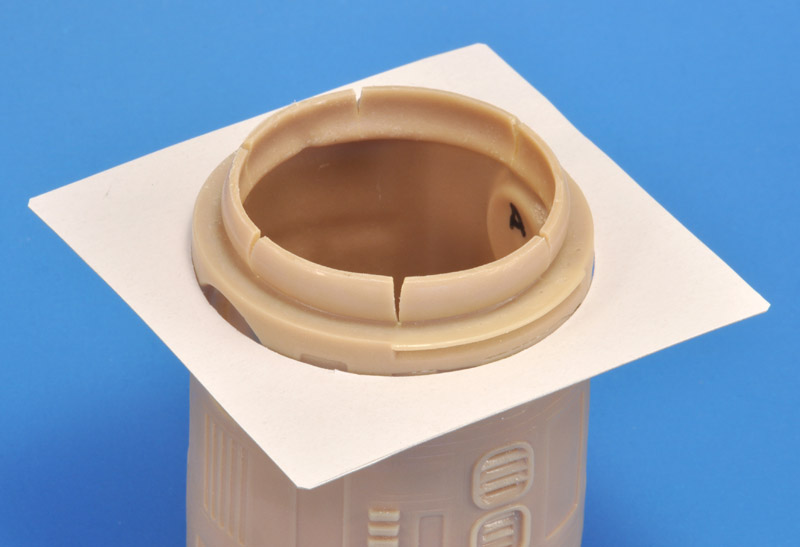

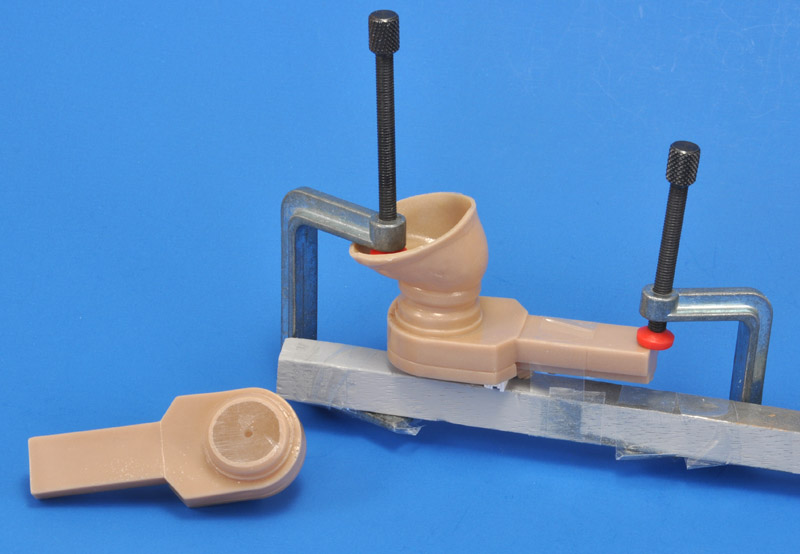

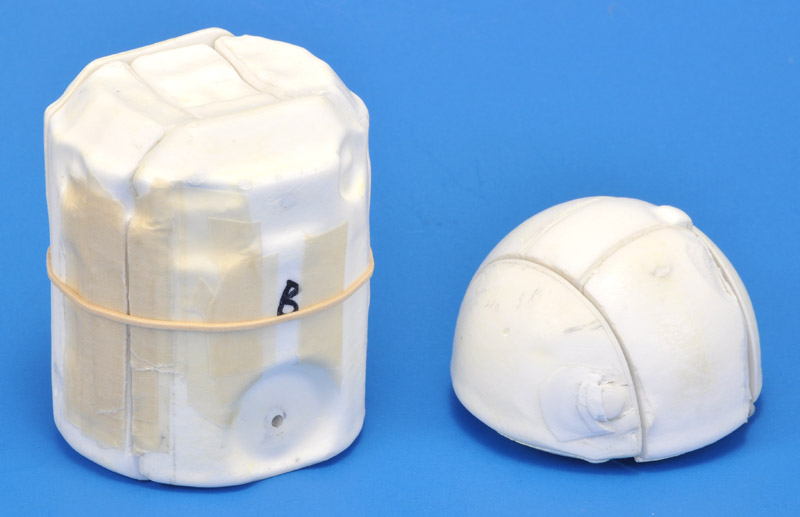

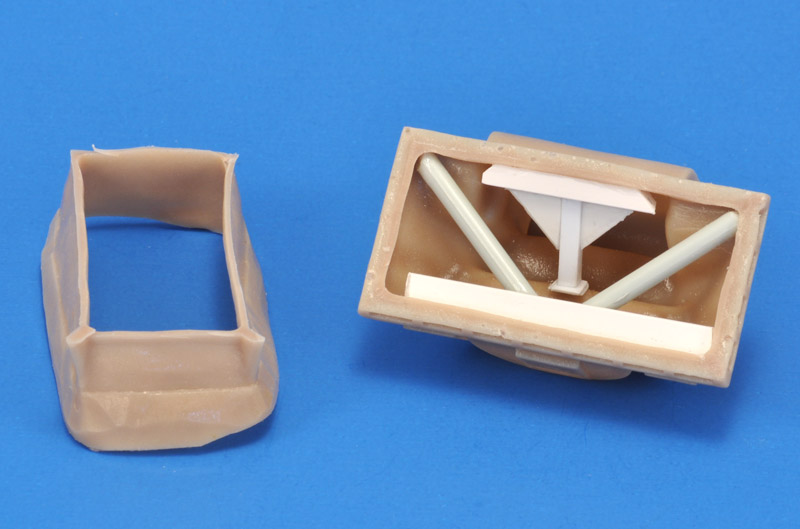

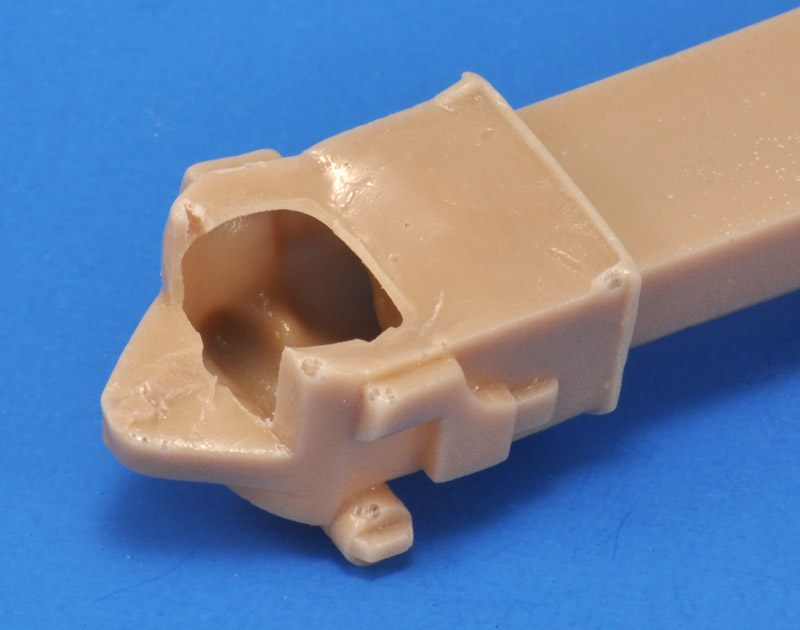

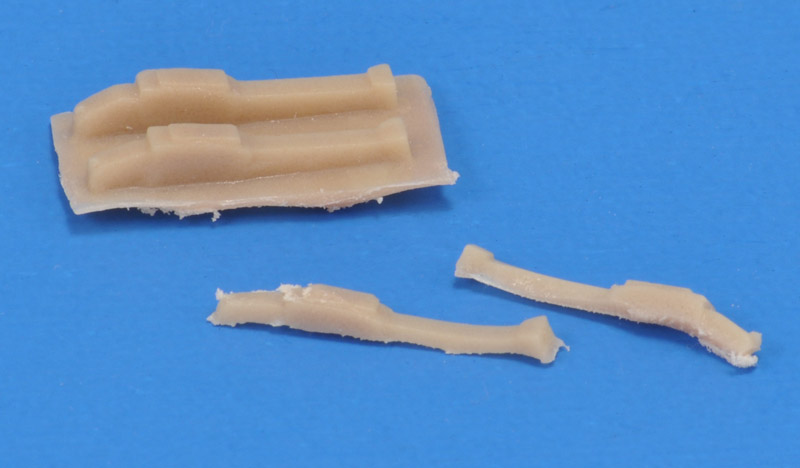

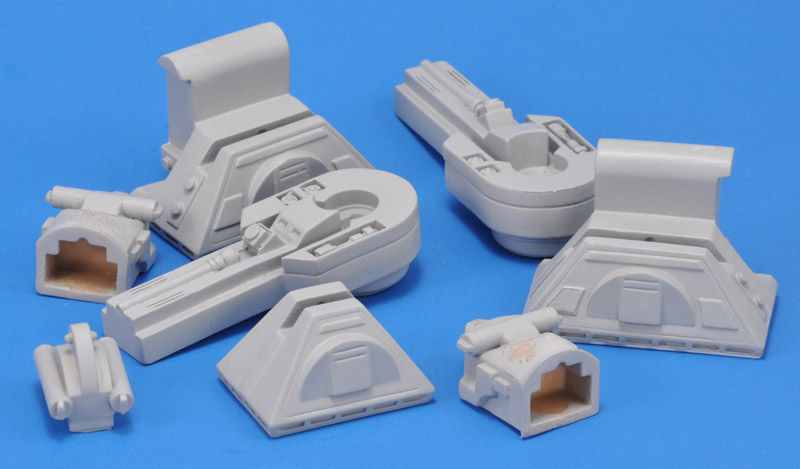

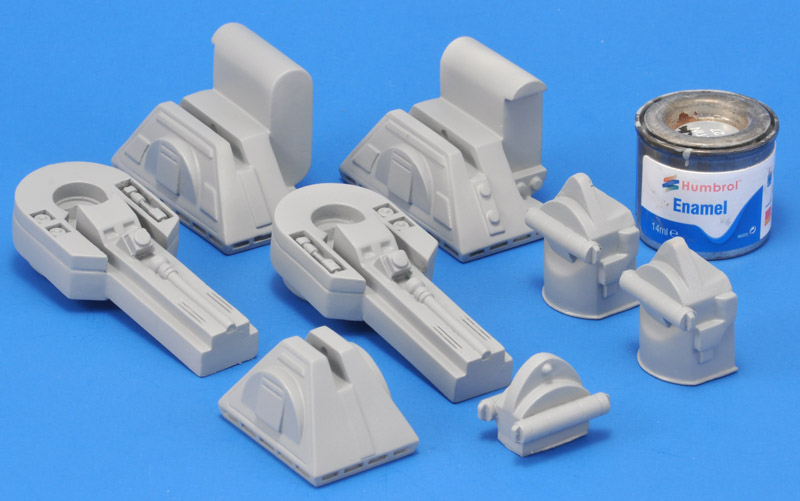

| Inspired by various articles in Fine Scale Modeler about vinyl models, I bought this kit in 2001, at Van Nieuwenhuizen in Rotterdam, for 37 euros. I wanted to see what this 'new' material was all about, but I picked the wrong subject. Vinyl parts are apparently always slightly warped, and for a 'technical' object like R2-D2 this easily becomes a real problem. My kit had various deformed parts. For years I looked for ways how to solve that.

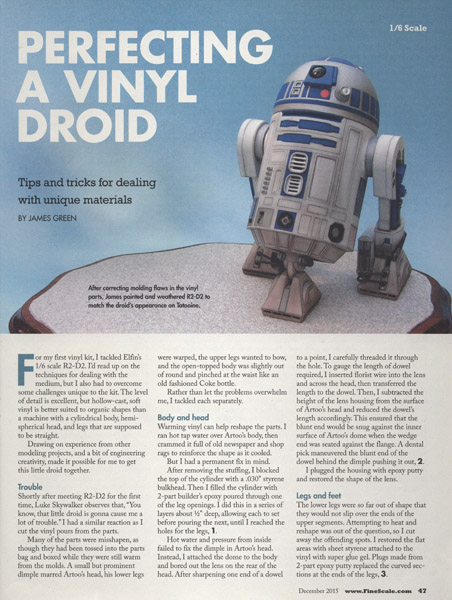

Slowly but surely I came up with a solution, but the amount of work held me back for a long time again. In the December 2015 issue of Fine Scale Modeler, an article about 'my' model was published, and it had similar deformations. That was comforting, and after a while I started the project. It's pretty crazy though. |