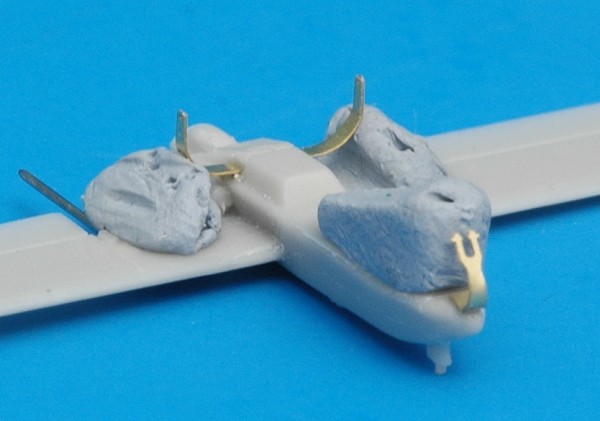

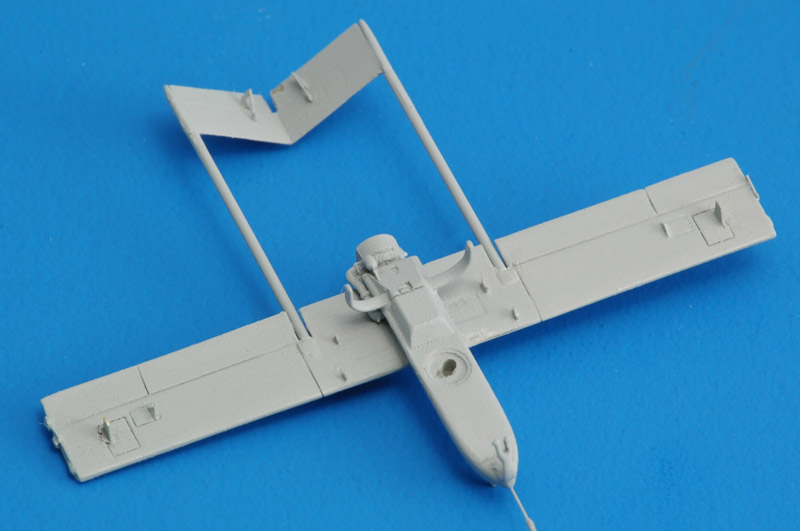

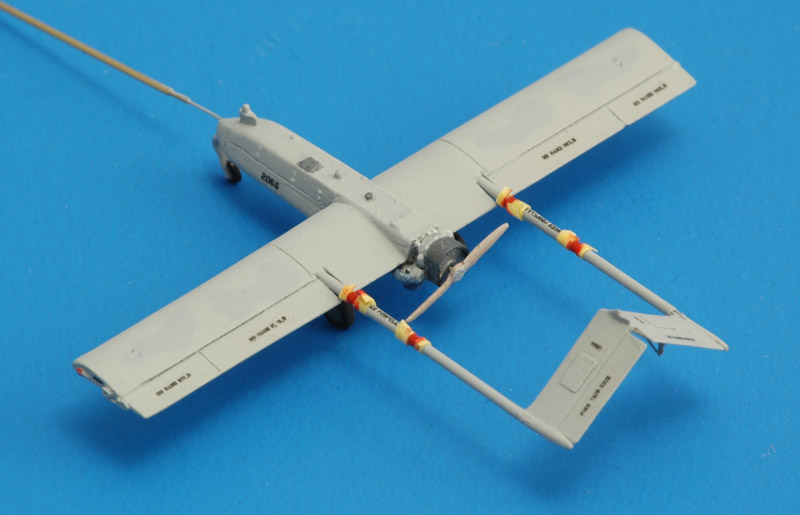

I base coat most of my models with Humbrol 127, and this happened to be the correct color of the RQ-7 (FS 36375), so no further painting was required. I added four camouflage patches, a mix of Humbrol 127 with a few drops of blue. I used 0.6 mm solder wire to create soft-edge masks of the patches. I surrounded the wire masks with Blu-Tack to keep them in place, and Maskol around that to mask the whole wing. The contrast was still too strong, so I misted Humbrol 127 over it. The instructions say the patches are FS 35270, but the latter color does not exist in the Federal Standard 595 A, B or C (I checked them all). I now think they meant 36270, but that color does not have the blue tint that I consistently see in photos.

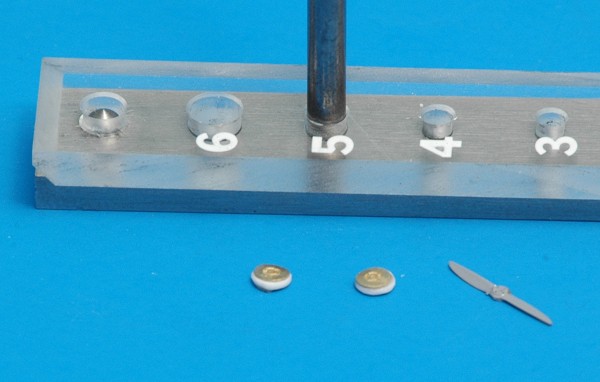

I also did some detail painting. Attack Squadron has no instructions, so I used photos. Various metallic colors were used for the engine, with a charcoal shroud. The propeller was painted a metallic goldish color. Buttons to open the nose cover were painted with a silver+white mix. Wingtips light red and green, other lights silver.

|

|