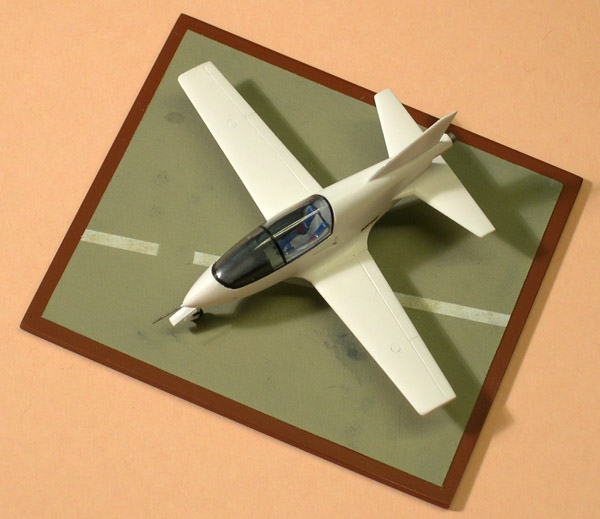

| In this side view you can see the putty applied to the fuselage to rear-fuselage-plus-stabilizer part. The canopy had its own problems. Apparently the mold was damaged since LS made it, and the ARII canopy looks quite horrible, with a pimple and many scratches. I cleaned it up using a Micro Mesh sanding set and Tamiya polish. The canopy also had flash, and it wouldn't fit in the fuselage opening. I probably sanded it too vigorously, and had to use Milliput to make it fit properly again. Due to the 'feathering' of the Milliput the repair looks larger than it is.

Update: this unintended canopy modification turns out to be an improvement. I compared the model's outline with the real thing, and the canopy is too big.

|