Custom decal design service

| I've been doing decal design for more than twenty years now. Time permitting, I do custom decal design work for other modellers, for a fee. On average, I do two to three assignments per year. This page presents information for modelers that consider having custom decals designed and printed.

|

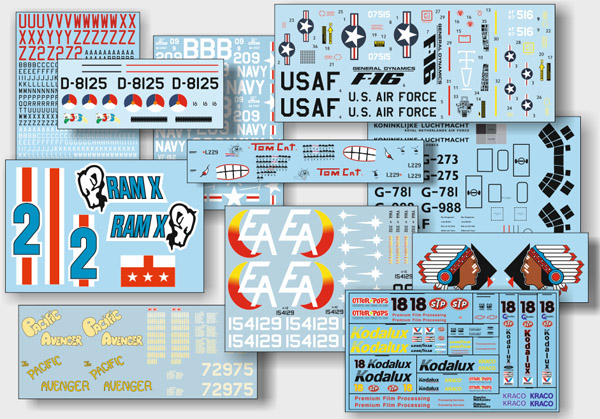

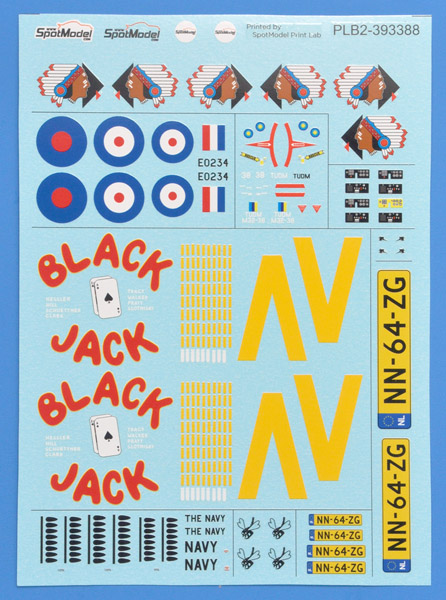

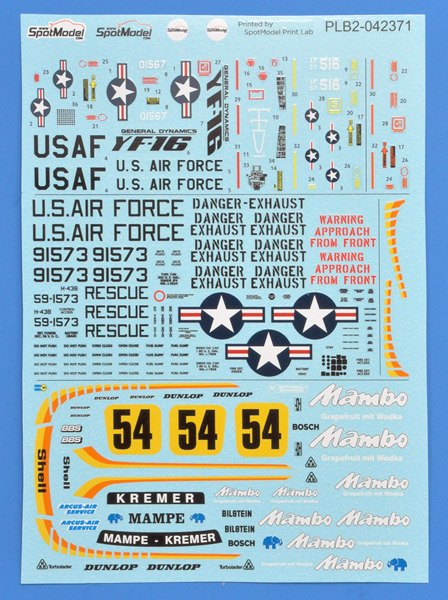

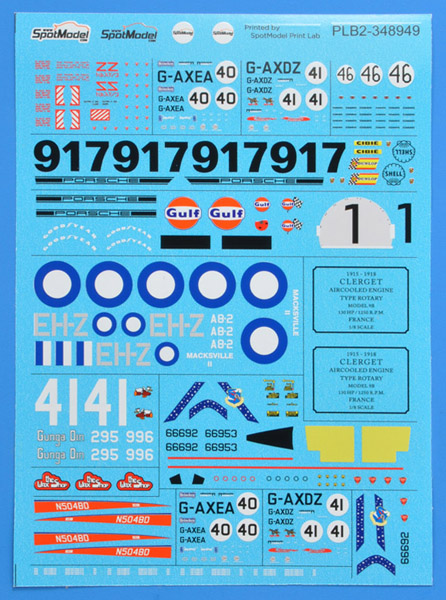

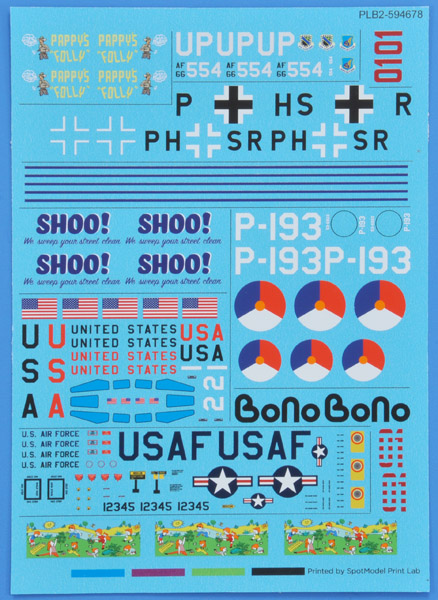

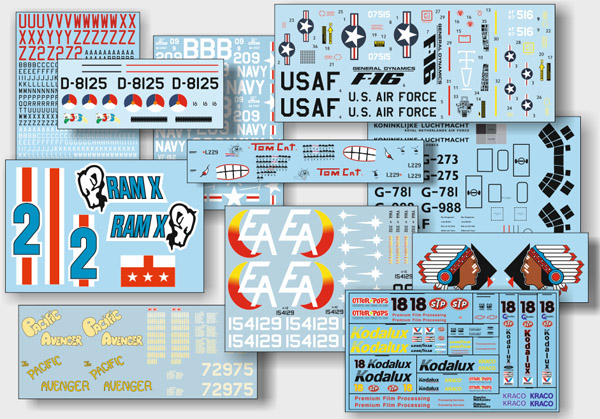

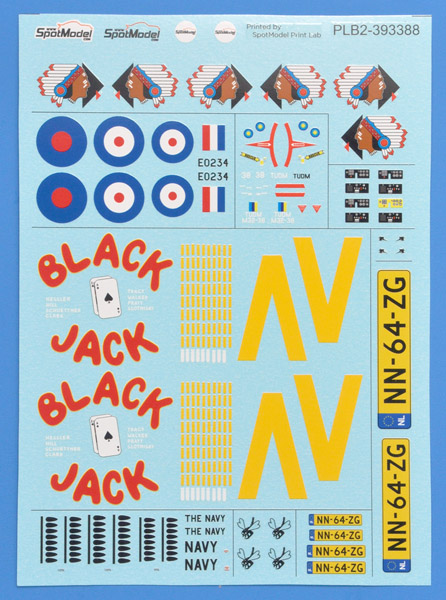

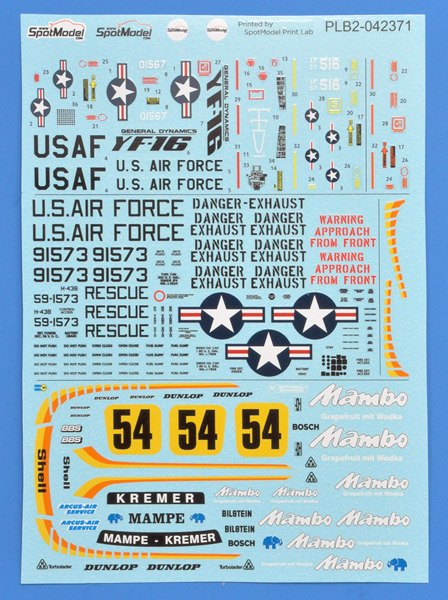

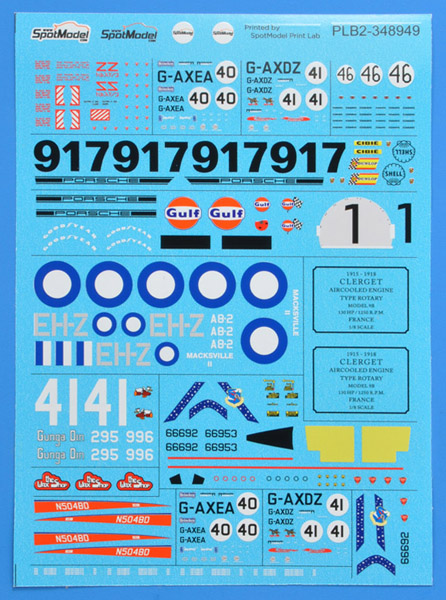

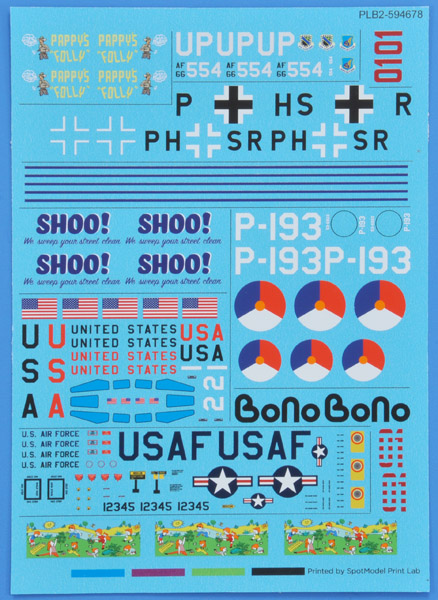

Sample sheets of custom decals

To start with the end result: here are four recent sheets of custom decals, of some thirty-four different projects. It covers aircraft, car and science fiction decals. The printing was done by SpotModel in Spain, since both my Alps printers broke down. I designed all of the artwork in CorelDraw.

How are custom decals created?

Decal artwork is created using vector graphics software, not bitmap graphics like Photoshop / Gimp / Corel Painter. Having JPGs or a scan of what you need is not sufficient for printing decals, they will have to be drawn again using vector graphics software. It takes an effort to learn vector graphics, and time to develop your skills so you can work efficiently. Most custom decal printers do not offer decal artwork design service - my best guess is that it takes up way too much time, something the customers often do not understand or appreciate. To address that last issue, I made six examples of various projects, to give you an idea of what's involved in creating custom decal artwork.

These examples show that producing decal artwork takes considerable time, effort, expertise and patience. Therefore, custom decals will be considerably more expensive than an aftermarket decal sheet. However, in many cases, you just need a few custom decals to do a project, because often the kit decals, or aftermarket decals, can provide the majority of the required decals. This limits the cost of doing a model with custom-made decals. But if you're not willing to spend money, please forget about having custom decals made.

Cost components

The main costs are the hours spent on drawing the artwork, using vector graphics software. Artwork scaling and preparing for printing is part of that. The second cost component is the communication with the customer. The customer knows what he wants, and needs to communicate all that information. Also, I'm usually no expert on the subject, and I probably need help from the customer. Count on at least a dozen of back-and-forth e-mails. The actual decal printing is relatively cheap, and I generally recommend doing a double set, just to be sure.

Cost versus scale

For a given set of decals, the hours spent on the artwork is the same regardless of scale, and hence the cost is roughly the same (printing costs will differ slightly). That makes custom decals relatively expensive for smaller scales. If you're building a 300 euros Liberator in 1/32 scale, 50 euros worth of custom decals probably won't bother you much. But if you're building a 1/72 Liberator worth 40 euros, those same but smaller set of custom decals will look very, very expensive.

Suggestions for cost reduction

One way or reducing your costs is the have multiple copies of the decals printed, and sell the extra sheets to other modelers. This could bring the cost down to the level of a regular aftermarket decal sheet. Drawbacks are that you will no longer have a unique model, and the effort required to sell the decals.

Preparations by the customer

Since communication takes time, and adds to the costs, it helps to come prepared as much as possible. Here's my list of suggestions what the customer can do to hit the ground running:

first are good photos on the 1:1 subject, of the highest resolution you can find. Side views are much better than oblique photos

if you scan photos, save them in high resolution, in the highest quality possible. If your scan has lots of JPG compression, lots of detail is lost again. Saving as a TIFF is always the safest option

make a clear list of the markings you need - I have no idea!

if you have color information, please report it

it is very helpful to provide a digital line drawing of the subject, in the highest resolution that you can find. This creates a great drawing board for the decal sizing. This drawing does not need to be in the scale of your decals; I can scale drawing easily. If you can add length, span and/or width figures, it helps to scale the drawing, and I don't have to look it up and calculate the scale figures. The drawings from the instruction sheet could be very useful

alternatively, side / front / top view photos of the model could work too. But they have to be made with a long lens, from a distance. Close-up photos with (for example) a telephone will give far too much perspective deformation

a last point to mention is that I'm often left guessing about the accuracy required by the customer. Some are desire the highest possibly accuracy, others are less demanding. Usually the accuracy level slowly becomes clear during communication, but it would be nice to know it beforehand. On the other hand, how does one express the required level of accuracy?

Please don't regard the above as a minimum, I've started with a lot less!

Printing

I have two Alps MD-5500 printers that are excellently suited for decal printing, but both are broken. Therefore, I cannot actually print your custom decals, and have to outsource the print jobs. I can also provide you with the artwork only, so you can send it to your favorite custom printer.

Print quality

Before I go into details: in all projects I've done so far, the customers have been very happy with the printed decals. But it is only fair to discuss the print quality of custom printed decals.

Generally speaking, the print quality of custom decals will be good, but they are slightly below the quality of modern series-printed decals. Do not expect Cartograf quality. When an Alps printer is used, the print will be very sharp, with text readable down to 0.3 mm high, but the color palette is limited - orange is an example of a very difficult color. When laser printers are used, the decals will not be as sharp as Alps decals, there will be some micro-splattering. Up close you can see some dithering in various colors. On the other side, the full palette of colors is available.

Color accuracy is another interesting aspect. Alps printers are fully predictable since (usually) solid layers of ink are printed on top of each other. But with laser printers, the outcome is less predictable, each printer has its own color profile. If color is critical, it could be wise to make decals with slight color variations, and use the ones you like best.

Delivery time

Generally speaking, I can do the artwork on short notice. But getting the decals printed can take a while. I need to fill an A5-size sheet (say half Letter) and that takes time, plus SpotModel works slowly. You don't have to pay until the printed decals are on my desk, ready for shipping.

If you are in a hurry, arrangements can be made. One solution is filling the A5-size sheet with multiple copies of your decals.

Do it yourself

You can find extensive decal design instructions elsewhere on my website: Design your own Alps / OKI custom decals.

Contact information

Please send your requests and/or questions to Rob de Bie.

Return to models page